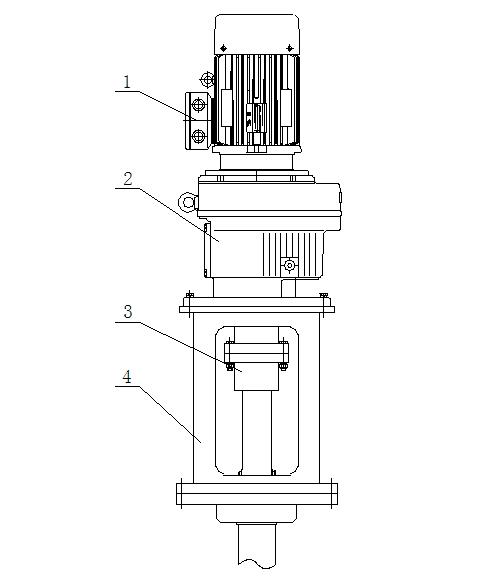

Top-entry Agitator

1、Motor: 1、Explosion proof type、Non-explosion-proof type

2、Energy-efficient type、Non-energy-efficient type

2、Reducer:1、R series(Coaxial type)

2、K series(Bevel gear type)

3、F series(Parallel shaft type)

3、Coupling:1、GT Rigid convex type

2、HL Cylindrical pin type

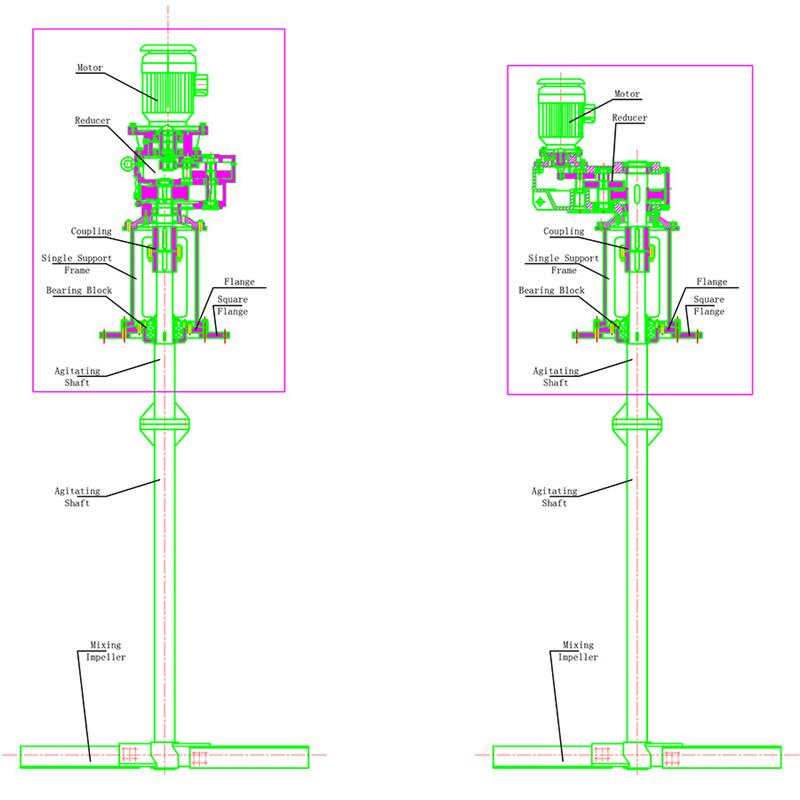

4、Frame: 1、DXJ Single support type

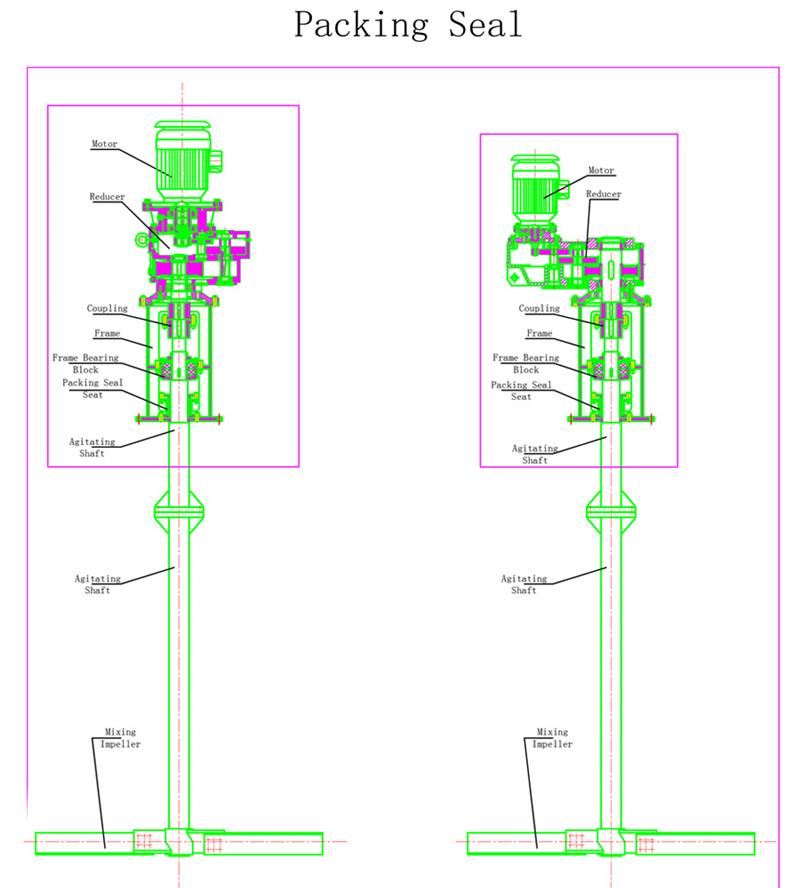

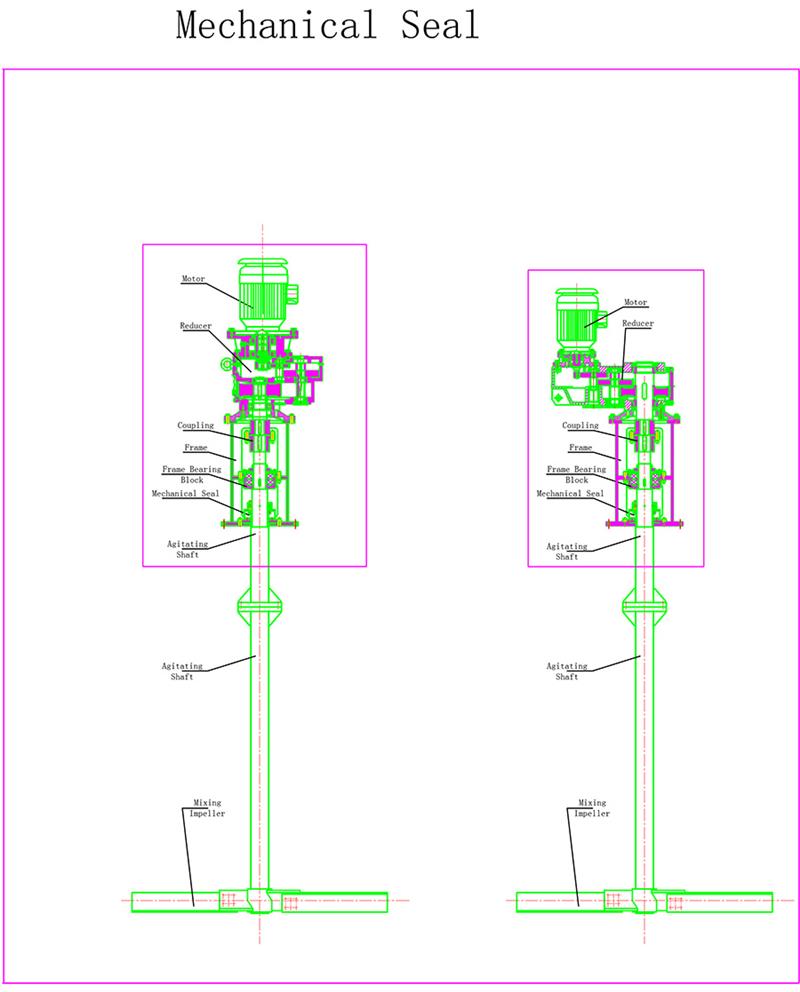

2、LDJ Single support type(can add mechanical seal or packing seal at the bottom of frame)

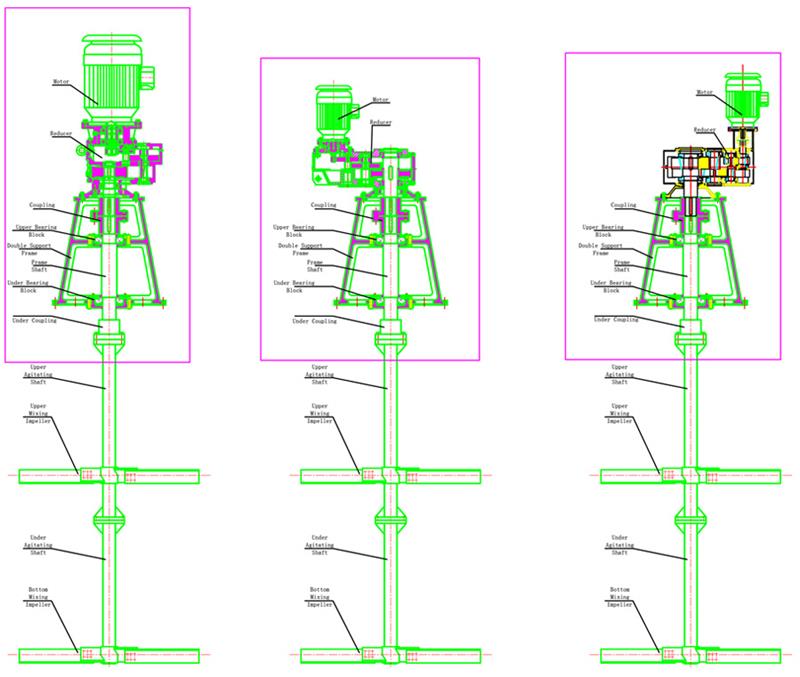

3、FZ Double support type

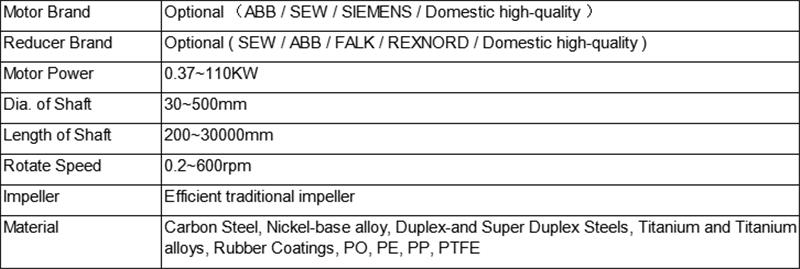

Agitator Parameter

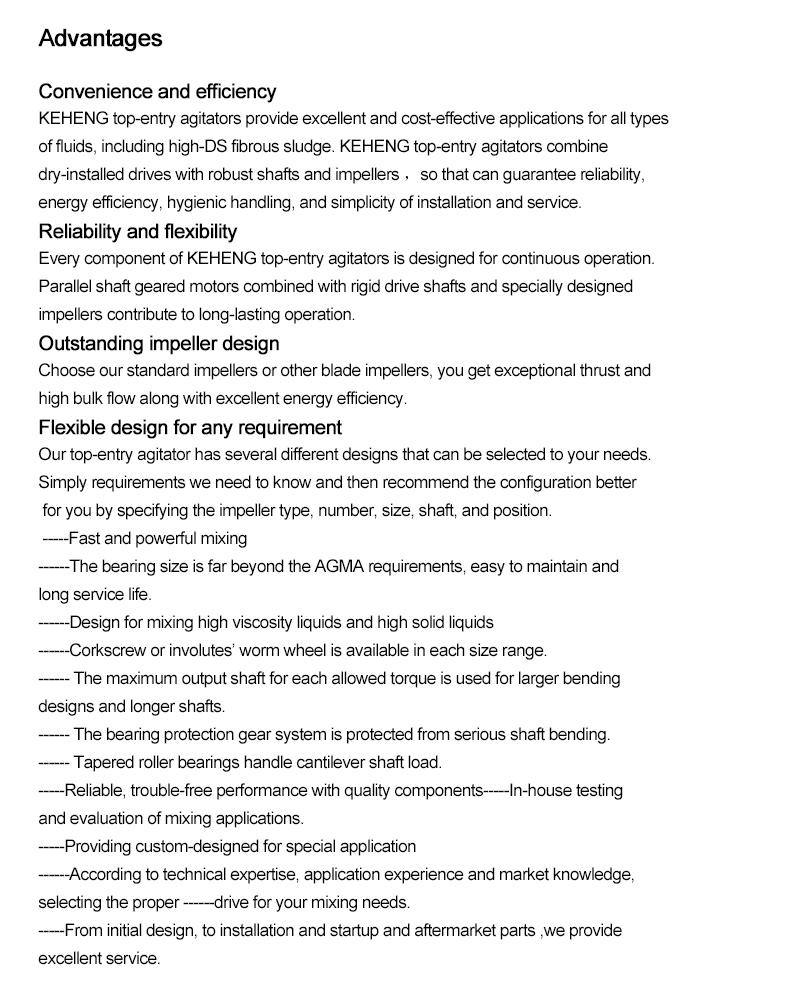

KEHENG top-entry agitator, since 1989, we have helped processing factories across the globe find the mixers and other equipment they need to meet their specific applications. Based on your specific mounting, flow pattern, and mixing requirements, we can help you select the top entry mixers that will best meet your needs, as well as suggest the impeller design and position that will offer a customized solution for nearly any agitation and mixing process. Our sales engineers are available to consult with you to determine which product or custom built equipment will be the best fit in your processing operation.

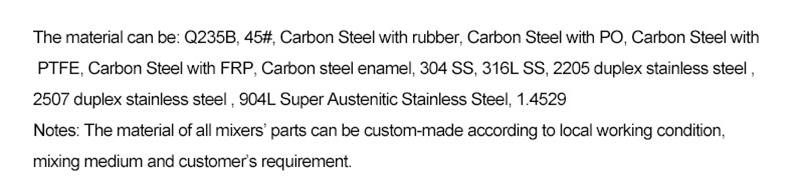

Material

Application

• Bulk chemical

• Polymer

• Specialty chemicals

• Formula consumer goods

• Bio-fuels and bio-refineries.

• Flue-gas desulfurization of Coal-fired plants

• Wet process

• Oil tank

Advantages of the reactor tank agitator

For chemical equipment, the reaction equipment is familiar to everyone, and it can be understood literally: it is a machine for material reaction, and the more commonly used reactors.

Generally, the structure of the reaction kettle is divided into a tank body, a head, a motor, a stirring device, a foot, and the like. The reactor agitator unit is the main unit for material mixing, so the choice of agitator is very important in daily production. ,

General reactor agitators can be divided into: paddle, blade, anchor, frame, ribbon screw, turbine (curved, folded, straight, push), Bruma gold, etc. Wait.

The most commonly used one is the paddle mixer.

Among the many stirring devices in the reaction kettle, the paddle agitator has the simplest structure. The whole blade is made of flat steel, and the connection is welded or bolted to the hub. The number of blades is generally 2, 3 or 4, and the blade form Generally, it can be divided into two types of flat leaves and folded leaves. According to the shape characteristics of the blades, the paddle type agitator can be divided into a flat paddle agitator and a tilt paddle agitator.

The flat paddle agitator produces a radial force that generally runs slower. About Zfl - 80r / min. Mixing occurs in the radial direction, and no good agitation occurs in the vertical direction. However, due to its simple structure, it is widely used to promote the mixing operation of heat transfer, mixing and dissolution of soluble solids.

The inclined paddle mixer produces axial force. The agitator blade can be inclined at 24°, 45° or 60°. It has axial splitting, radial splitting, and the flow pattern is more complex than the straight blade paddle. It is higher than the straight paddle, and the comprehensive effect is better. The applicable process is the same, so the application frequency is higher than that of the straight blade paddle, and the operating conditions are the same as the straight blade paddle type.

Therefore, when the reactor agitator is configured as a paddle type, it is generally suitable for a low viscosity liquid, and the suspension and the solution are stirred. For medium to high viscosity materials, it is not recommended to use a reactor equipped with a paddle stirrer.

Hot Tags: reactor tank agitator, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China