Introduction of CV-Type Side-entry mixer:

Installing a side-entry mixer in the oil tank, is used for mixing oils or other medium and then reach the purpose of harmonization, heat transfer , homogenization and prevention of sediment accumulation.

Using this equipment has many advantages, such as small investment, convenient operation, high efficiency, low power consumption, low static electricity generated in medium and guarantee product quality.

CV-Type Side-entry mixer can be installed in petroleum tank, lubricating tank, fuel oil drum, paraffin tank and some storage tanks for additive and other medium which need to be stirred.

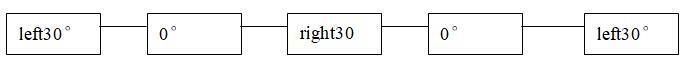

Swing Angle changes of CV-Type Side-entry mixer:

The variable insertion Angle type agitator is used to prevent the accumulation of sediments, and the change of rotation Angle as follows

Material

The material can be: Q235B, 45#, Carbon Steel with rubber, Carbon Steel with PO, Carbon Steel with PTFE, Carbon Steel with FRP, Carbon steel enamel, 304 SS, 316L SS, 2205 duplex stainless steel , 2507 duplex stainless steel , 904L Super Austenitic Stainless Steel, 1.4529

Notes: The material of all mixers’ parts can be custom-made according to local working condition, mixing medium and customer’s requirement.

The mixer is mainly used to mix, harmonize, accelerate the heat transfer. It can maintain medium temperature and prevent sediment accumulation in the tank.

The Belt Side Entry Mixer and the Forward Rake Advanced Pitch Propeller represent next-generation innovations for petroleum and fuel storage tanks. This mixer is also one of the most efficient crude oil tank mixers on the market. It was designed with and for operators to improve efficiency, blend product or oils more rapidly, and allow for timely and economical maintenance in the field.

Crude oil tank mixers and industrial blender

Stirring plays a very important role in accelerating the reaction between mutually incompatible liquids or when liquids and solids interact. Because the rate at which one phase is mixed into the other phase increases, the contact surface increases. Matters interact at a greater rate. In some cases, agitation is an important factor in good conditions during the reaction. For example, heat transfer is enhanced, local overheating is reduced, and material coking during heating is avoided. For example, in the production of high-pressure polyethylene, due to the action of stirring, the material has a certain residence time in the reactor, and more importantly, the catalyst is evenly distributed in the device to prevent local violent polymerization and cause explosion. Therefore, the stirring equipment plays a very important role in industrial production.

Mixing equipment is used in petrochemical production for material mixing, dissolution, heat transfer, suspension preparation, polymerization, preparation of catalysts, and the like. For example, in the petroleum industry, mixing adjustment and refining of dissimilar crude oils, and addition of additives such as tetraethyl lead to gasoline are carried out to homogenize the raw material liquid or product. In chemical production, processes such as styrene, ethylene, high-pressure polyethylene, polypropylene, synthetic rubber, aniline dyes and paint dyes are equipped with various types of mixing equipment. In the petroleum industry, because of the large number of catalysts and additives, the amount of mixing equipment required is large. Due to the complexity and variety of material handling conditions, the requirements for mixing equipment are also complicated.

Hot Tags: tank oil mixers, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China