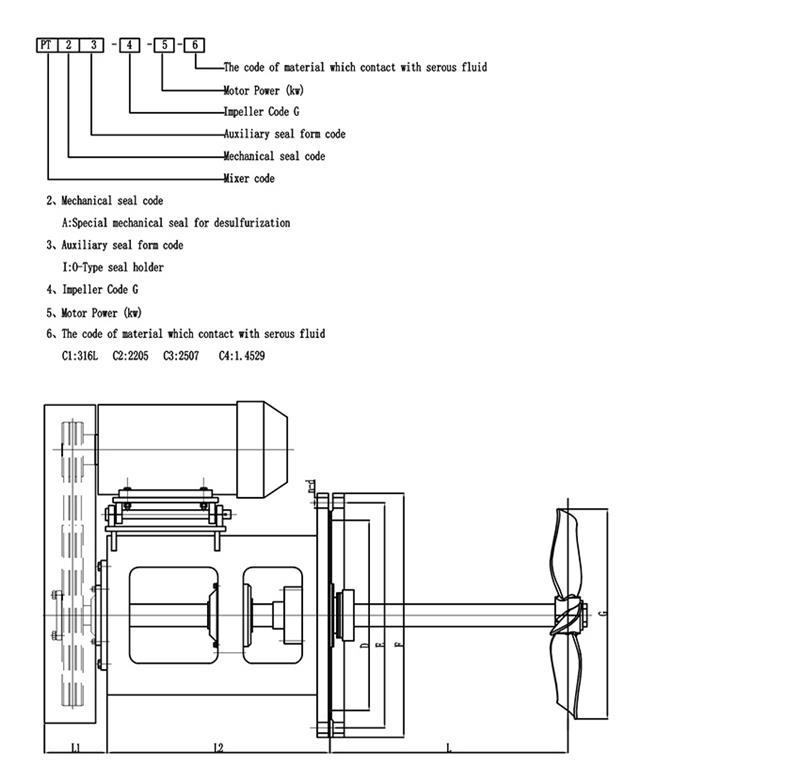

Introduction of PT-Belt-Type side-entry mixer:

Use of flue gas desulfurization: mainly prevent the solids setting from the slurry tank and ensure that the slurry can be transported uniformly to the next process. Strengthen the diffusion of oxidized air, also promote the oxidation of calcium sulfite, the growth of gypsum crystal and the dissolution of limestone.

Using this equipment has many advantages, such as small investment, convenient operation, high efficiency, low power consumption, low static electricity generated in medium and guarantee product quality.

This type of mixer also can be used for wastewater treatment and paper-making industry.

Material

The material can be: Q235B, 45#, Carbon Steel with rubber, Carbon Steel with PO, Carbon Steel with PTFE, Carbon Steel with FRP, Carbon steel enamel, 304 SS, 316L SS, 2205 duplex stainless steel , 2507 duplex stainless steel , 904L Super Austenitic Stainless Steel, 1.4529

Notes: The material of all mixers’ parts can be custom-made according to local working condition, mixing medium and customer’s requirement.

What are the working parts of the stainless steel side-in type agitator?

The stainless steel side enter agitator is divided into three parts: working part,supporting part and driving part. In the working part, includes a stirrer, a stirring shaft (including a coupling) and a stirring attachment; In the supporting part ,includes a base and Bearing device; In the drive part , includes an electric motor (also called a motor or motor) and a speed reducer, etc.

The stainless steel side-in type agitator working part:

1. Agitator: Also known as mixer, it is generally considered from three aspects, the purpose of mixing, the viscosity of the material and the volume of the agitator. In addition to meeting the process requirements, the power consumption, operating costs, and manufacturing, maintenance, and overhaul factors are also considered.

2. Agitator shaft: fix the agitator and take power from the output shaft of the deceleration device. When the agitator is rotated, the power is transmitted to the agitator to overcome the resistance moment encountered during the rotation to work on the fluid. The agitating shaft includes a journal (support portion), a shaft head (mounting member), and a shaft body (a rod portion). Commonly used materials: 45 high quality steel, 35 steel, stainless steel, etc.

Coupling: The two independent shafts are firmly connected together to transmit rotational motion and power. The main requirement is to ensure that the two coupling shafts are concentric and sometimes have a certain ability to reduce shocks and mitigate shocks. The main types include: flange couplings, cage couplings, sleeve couplings, and elastic ring pin couplings.

3. Stirring accessories: including baffles and diversion tubes

Hot Tags: stainless steel mixing tank with agitator, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China