Introduction of P-Belt-Type side-entry mixer:

Installing a side-entry mixer in the oil tank, is used for mixing oils or other medium and then reach the purpose of harmonization, heat transfer , homogenization and prevention of sediment accumulation. Using this equipment has many advantages, such as small investment, convenient operation, high efficiency, low power consumption, low static electricity generated in medium and guarantee product quality.

P-Belt-Type Side-entry mixer can be installed in petroleum tank, lubricating tank, fuel oil drum, paraffin tank, asphalt tank (for heavy rubber asphalt, basic petroleum bitumen, A Grade asphalt) and some storage tanks for additive and other medium which need to be stirred.

Material of oil tank agitator

The material can be: Q235B, 45#, Carbon Steel with rubber, Carbon Steel with PO, Carbon Steel with PTFE, Carbon Steel with FRP, Carbon steel enamel, 304 SS, 316L SS, 2205 duplex stainless steel , 2507 duplex stainless steel , 904L Super Austenitic Stainless Steel, 1.4529

Notes: The material of all mixers’ parts can be custom-made according to local working condition, mixing medium and customer’s requirement.

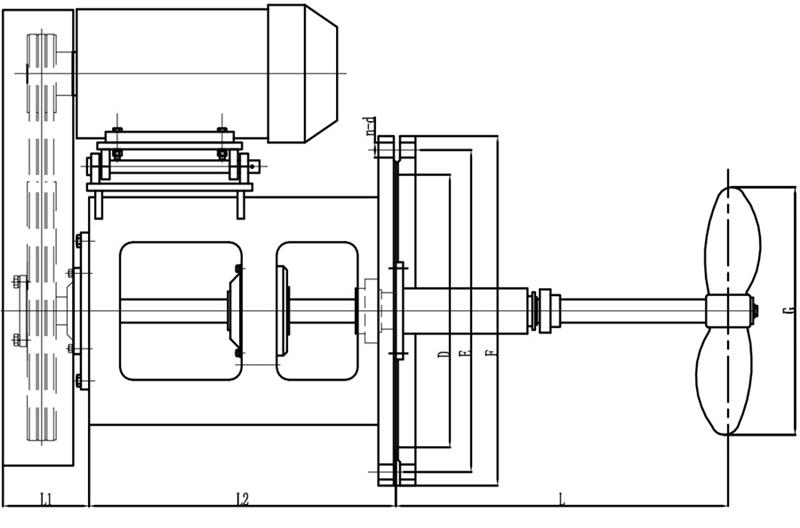

How the lateral extension stirrer works in a crude oil storage tank

The lateral extension stirrer consists of a motor, a reduction gear, a main shaft, a sealing device, an impeller, etc., and is connected by a flange and mounted on the side wall of the crude oil storage tank. Its working principle: there is a motor device in the lateral extension type agitator, and the motor device is used to drive the rotation of the blade in the oil tank through the reducer, so that the medium in the oil tank can circulate and flow, and then the fusion and heat are performed. The transfer, so that the deposits in the tank are homogenized, so that the deposits can not be aggregated, and finally with the crude oil together with the hair.

Hot Tags: oil tank agitator, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China