Top-entry Agitator

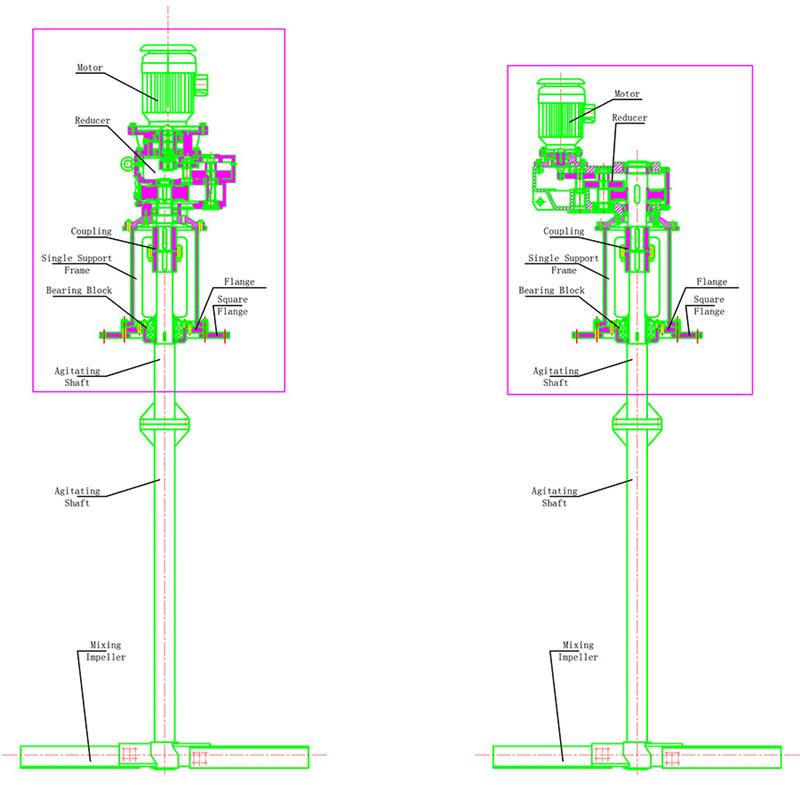

1、Motor: 1、Explosion proof type、Non-explosion-proof type

2、Energy-efficient type、Non-energy-efficient type

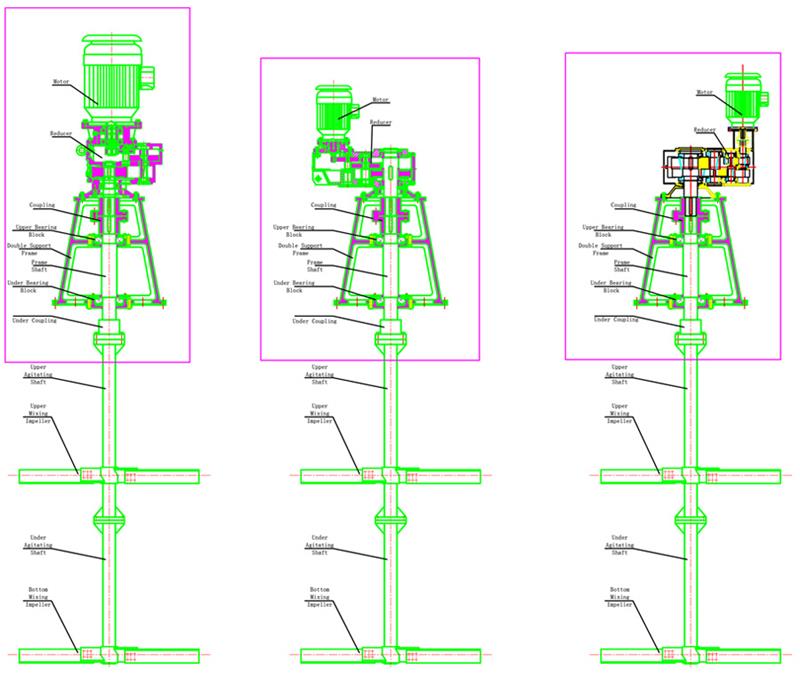

2、Reducer:1、R series(Coaxial type)

2、K series(Bevel gear type)

3、F series(Parallel shaft type)

3、Coupling:1、GT Rigid convex type

2、HL Cylindrical pin type

4、Frame: 1、DXJ Single support type

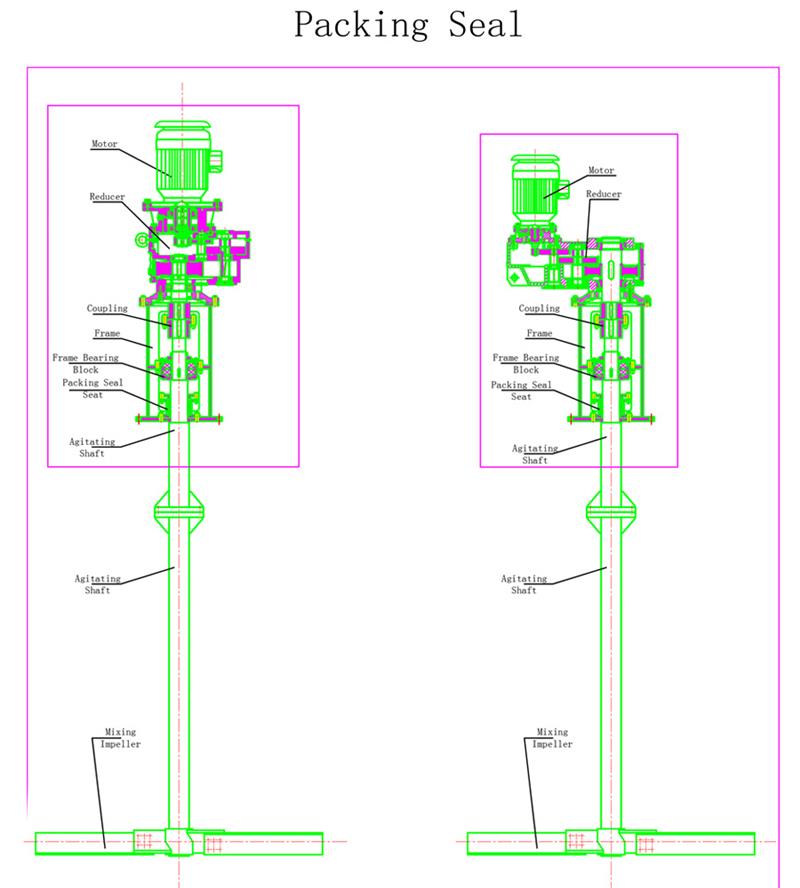

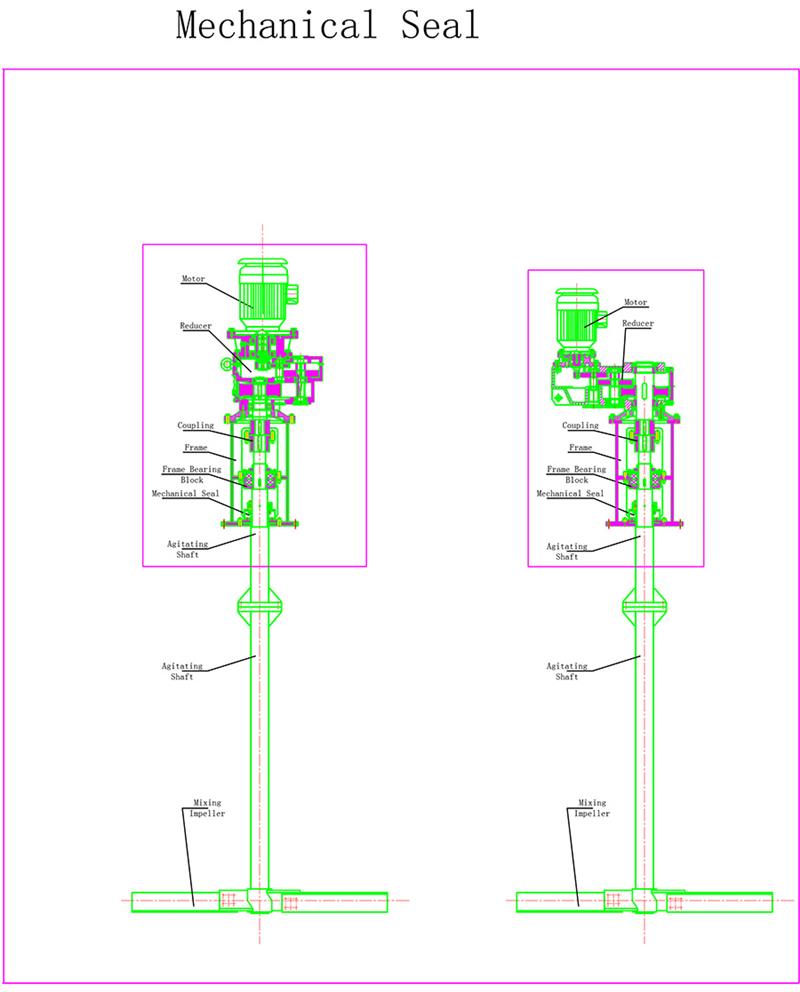

2、LDJ Single support type(can add mechanical seal or packing seal at the bottom of frame)

3、FZ Double support type

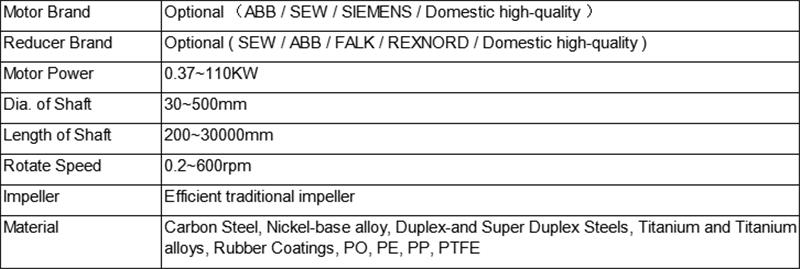

Agitator Parameter

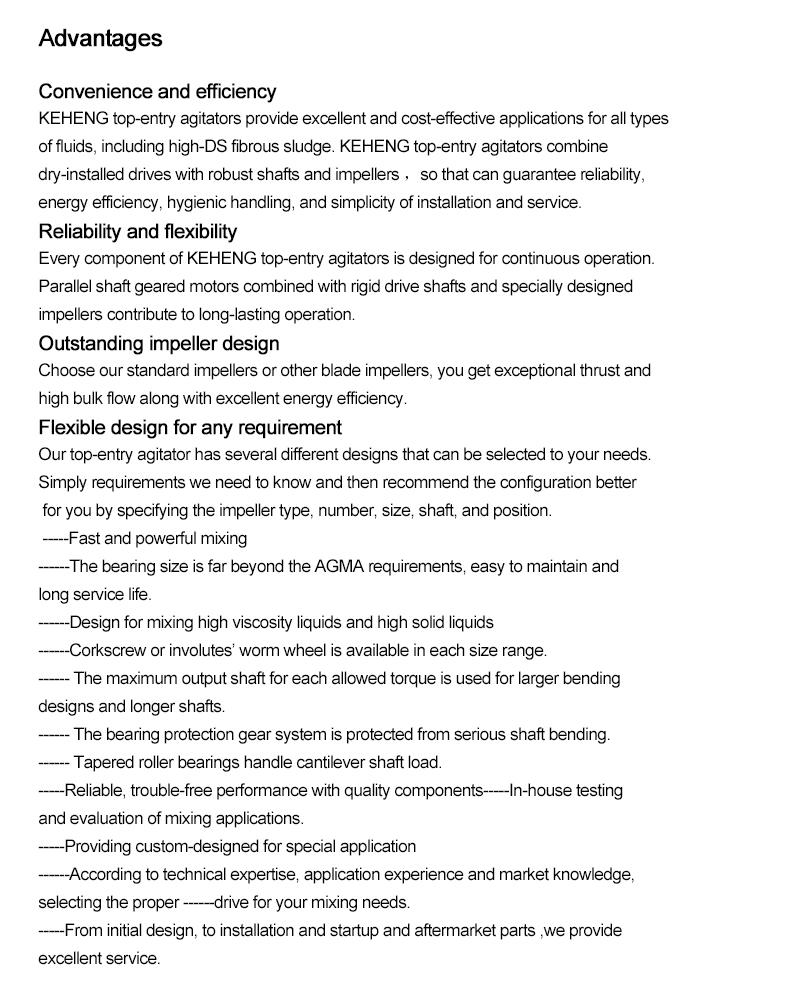

KEHENG top-entry agitator, since 1989, we have helped processing factories across the globe find the mixers and other equipment they need to meet their specific applications. Based on your specific mounting, flow pattern, and mixing requirements, we can help you select the top entry mixers that will best meet your needs, as well as suggest the impeller design and position that will offer a customized solution for nearly any agitation and mixing process. Our sales engineers are available to consult with you to determine which product or custom built equipment will be the best fit in your processing operation.

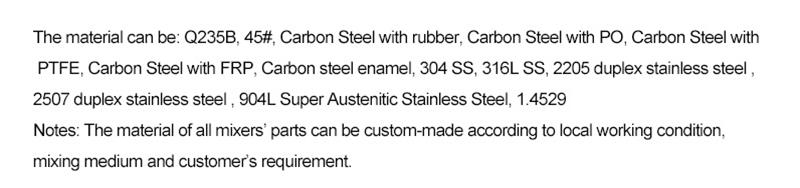

Material

Application

• Bulk chemical

• Polymer

• Specialty chemicals

• Formula consumer goods

• Bio-fuels and bio-refineries.

• Flue-gas desulfurization of Coal-fired plants

• Wet process

• Oil tank

Vertical mixer installation flow

1. The installation of the vertical mixer requires a high level of installation level for the reactor. After the reactor is fixed, the level of the flange of the kettle must be between 0.10 and 0.15 mm. The level of the flange of the kettle mouth directly affects the amount of swing of the agitator shaft.

2/1000. The radial direction of the lower end of the shaft is not more than 0. 5 / 1000.

3. You must carefully read the instruction manual and installation diagram before installation. ;

4. For the reaction kettle with manhole, the installation sequence of the reducer is generally: 1 the agitator shaft is placed in the kettle, the shaft head is exposed to the kettle port, 2 sets of mechanical seals are attached, 3 the upper frame is mounted, and 4 the reducer is installed. Install the intermediate bearing or bottom bearing -6 in the kettle to install the stirrer. When installing the mechanical seal, care must be taken to apply a clean oil film to the O-ring. It should be handled gently and not slammed. For double-faced mechanical seals, they have been debugged before leaving the factory and cannot be disassembled at will. For single-end mechanical seals, the vertical mixer needs to be commissioned on site after installation: first adjust the spring specific pressure (202 type spacing 10~11mm, 204 type spacing 5~6mm), and then adjust the static ring gland. The tightness of the bolt (the whole adjustment process is actually adjusting the vertical seal surface and the verticality of the shaft). Finally, if there is a slight leak, it can be removed by dry running for 1~2 hours.

5mm; and the lightness of the hand movement is light, the amount of the radial runout of the shaft at the shaft seal should be less than 0.2mm for the packing seal; Flexible, no jamming.

6. Before installing the gear unit, it is necessary to clean and burr the opposite joint surfaces, especially the sealing surface.

Hot Tags: large tank agitator, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China