Top-entry Agitator

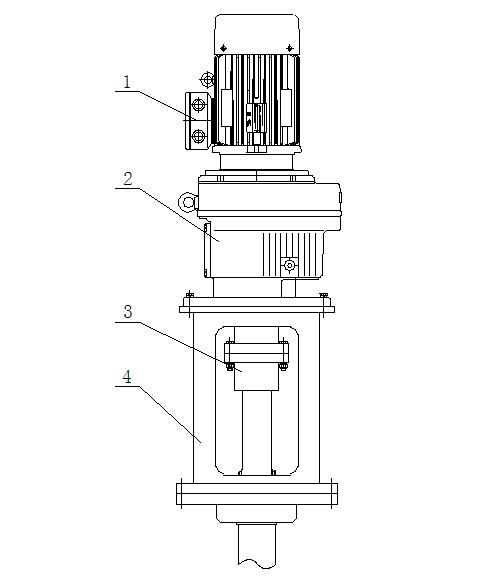

1、Motor: 1、Explosion proof type、Non-explosion-proof type

2、Energy-efficient type、Non-energy-efficient type

2、Reducer:1、R series(Coaxial type)

2、K series(Bevel gear type)

3、F series(Parallel shaft type)

3、Coupling:1、GT Rigid convex type

2、HL Cylindrical pin type

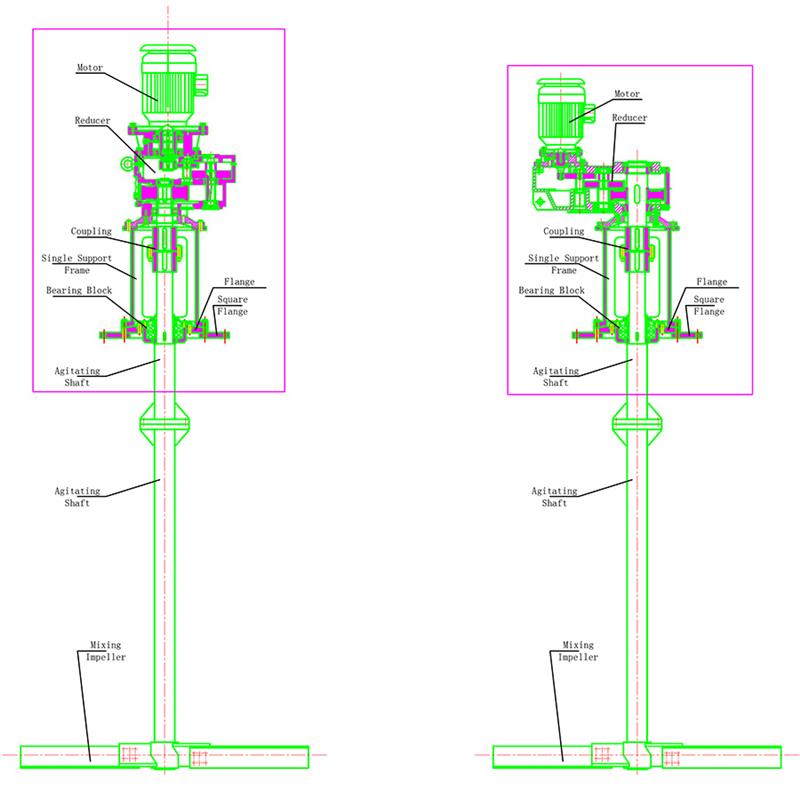

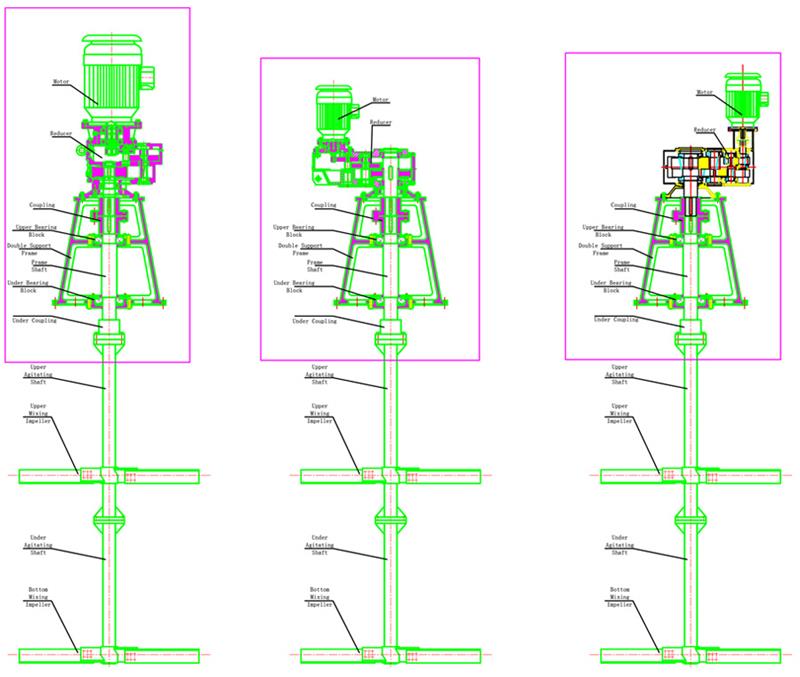

4、Frame: 1、DXJ Single support type

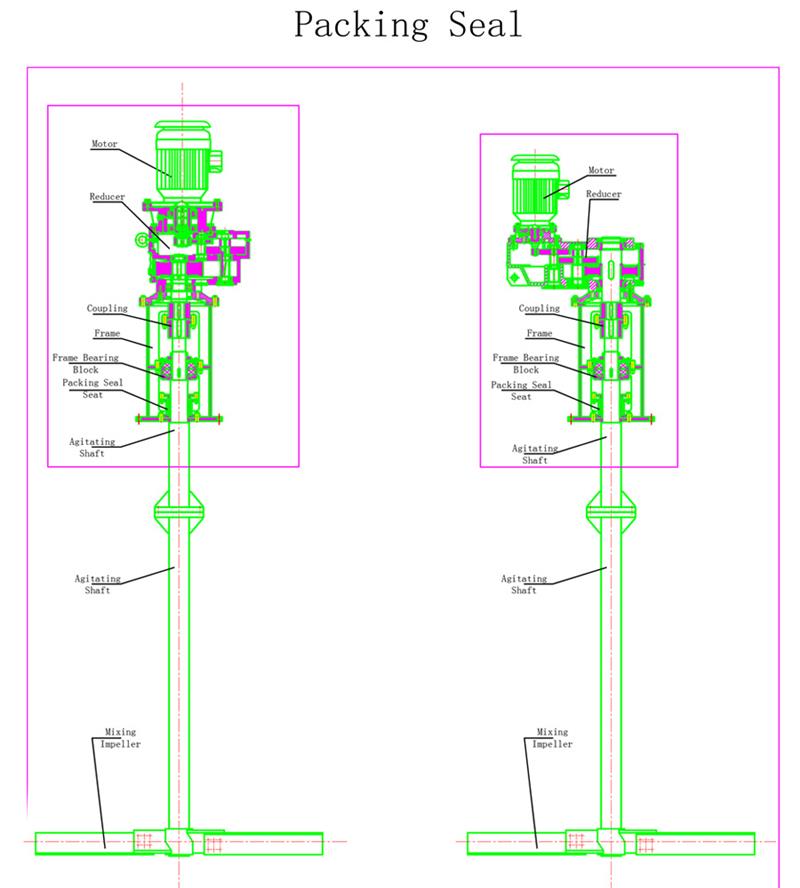

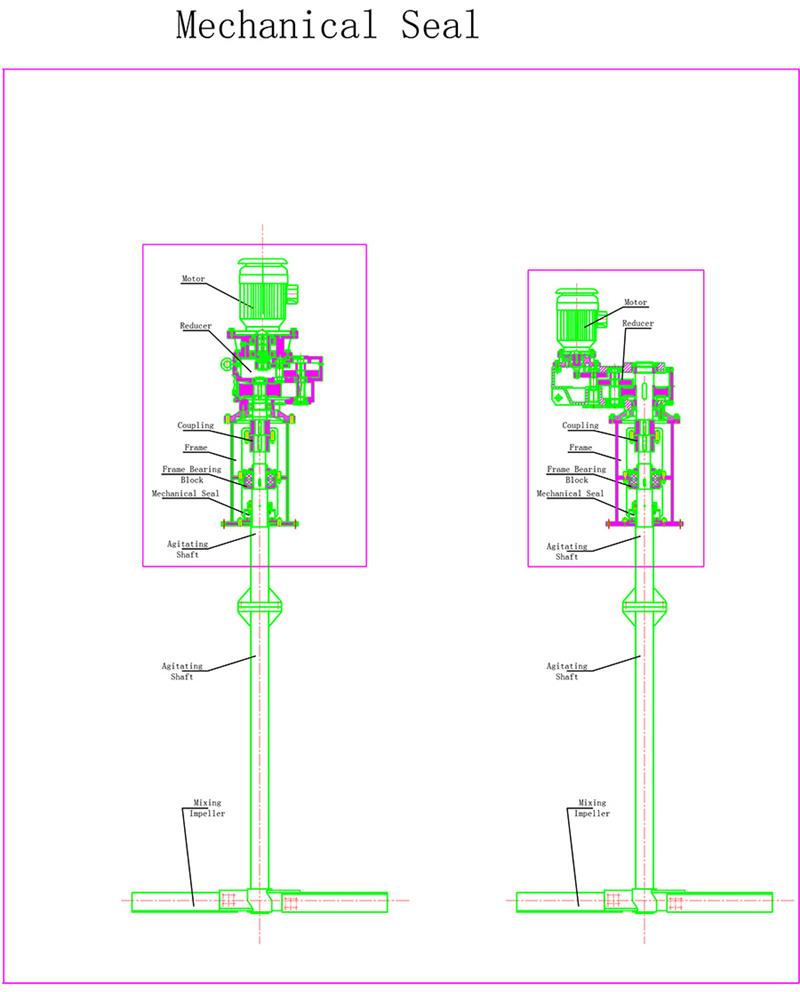

2、LDJ Single support type(can add mechanical seal or packing seal at the bottom of frame)

3、FZ Double support type

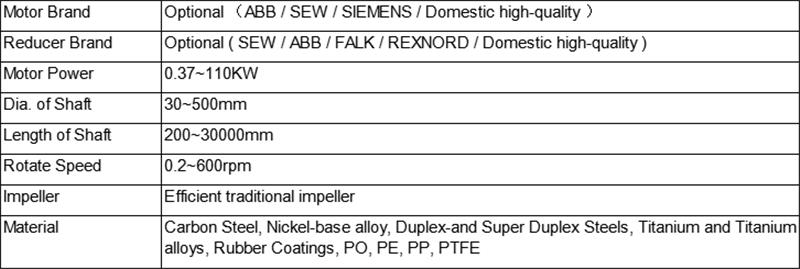

Agitator Parameter

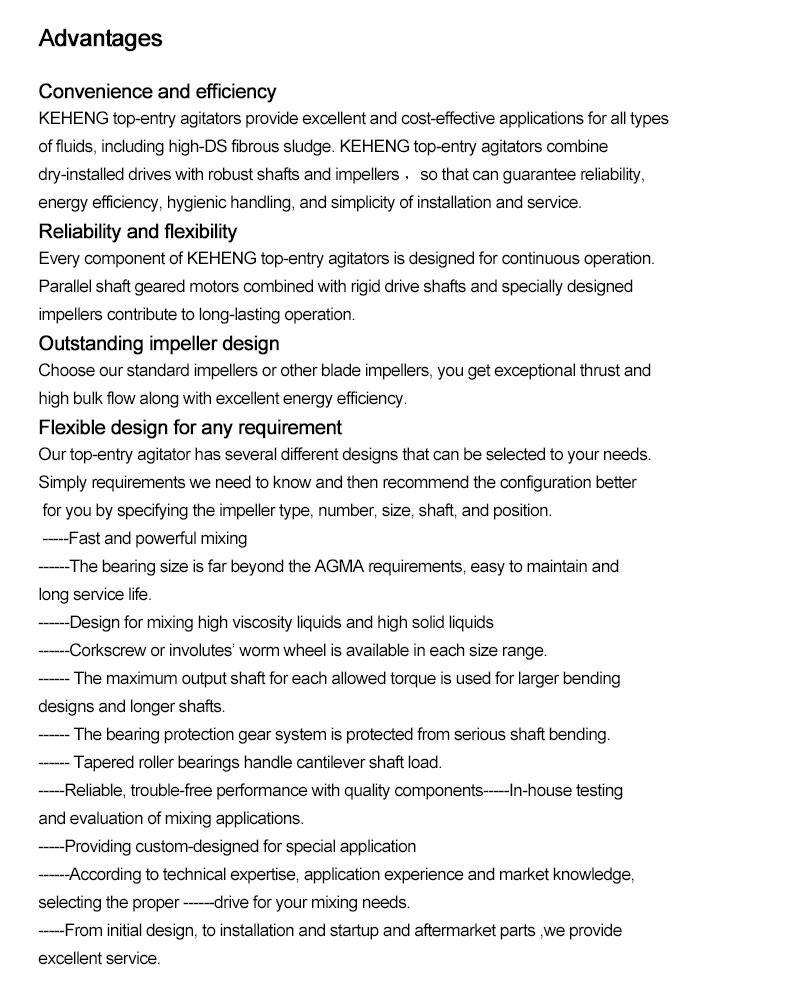

KEHENG top-entry agitator, since 1989, we have helped processing factories across the globe find the mixers and other equipment they need to meet their specific applications. Based on your specific mounting, flow pattern, and mixing requirements, we can help you select the top entry mixers that will best meet your needs, as well as suggest the impeller design and position that will offer a customized solution for nearly any agitation and mixing process. Our sales engineers are available to consult with you to determine which product or custom built equipment will be the best fit in your processing operation.

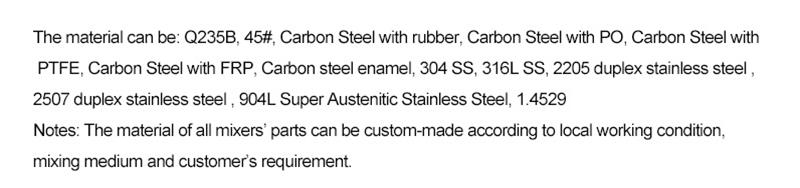

Material

Application

• Bulk chemical

• Polymer

• Specialty chemicals

• Formula consumer goods

• Bio-fuels and bio-refineries.

• Flue-gas desulfurization of Coal-fired plants

• Wet process

• Oil tank

What is the tank liquid agitator?

What is the liquid agitator that is widely used in the chemical, pharmaceutical, metallurgical, food and water treatment industries? Next, let the decoration industry Xiaobian bring you a brief introduction of the liquid mixer. The working principle of the liquid mixer The work of the liquid mixer is to use the belt of the electric motor to drive the impeller, so that the rotating impeller can fully mix the medicine and the slurry, which is one of the indispensable mechanical equipments in the mining and chemical industry.

The liquid mixer of the liquid mixer is also called liquid_liquid and liquid-solid state collection mixer, vertical mixer, mainly used for mixing and stirring between liquid liquid and liquid-solid. Unlike powder mixers which are primarily used to prepare mutually insoluble liquid mixtures, liquid mixers are used to process mutually soluble or mutually insoluble liquid mixtures. The liquid mixer can be used for the agitation work before the metal ore flotation, and the purpose is to achieve thorough mixing of the agent and the slurry. The liquid mixer is also used to mix liquids of different colors and specific gravity, or to bring the solid particles into a suspended or turbid state in the liquid in a liquid-solid mixture. At the same time, in the mixing, heat exchange between the liquid and the container can be promoted to prevent local overheating. The data parameters of the liquid mixer usually use the cylindrical inner tank, which is divided into two types: the closed type and the open type. The main components include the motor, the reducer and the frame. The stirrer consists of the coupling, the shaft and the vane. composition. In the preparation of the mixer data parameter table, attention should be paid to the parameters of mixing purpose, speed requirement, tank type, tank size, dynamic and static load, dynamic and static torque, power input, wear corrosion and resonance. Precautions for Selection of Liquid Mixer The standard material of the liquid mixer is SUS304. When there is special requirements for explosion protection of the motor, the liquid mixer should be selected according to its protection level. If there is a need for high-speed agitation or large-capacity agitation, equipment with a retaining ring and shaft seat protection should be selected.

Precautions for use of liquid mixer

1. The liquid mixer should start the power supply after confirming that the input voltage does not exceed the specified voltage and current load on the motor nameplate.

2. It is forbidden to run the empty car before the blade is completely immersed in the liquid: to avoid the danger of equipment damage.

3, the equipment should have a tough enough fixed foundation, the working environment should have no common vibration.

4. Before starting the power supply, check that the bolts and screws are fully fixed.

5. If the mixer has abnormal noise, temperature rise, shaking, etc. during operation, it should be stopped immediately for inspection.

Hot Tags: tank liquid agitator, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China