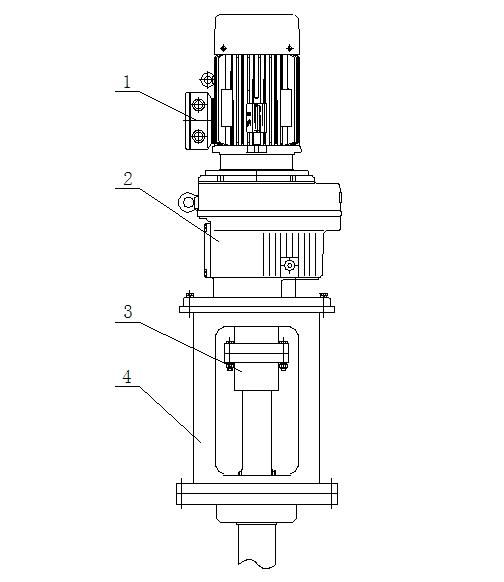

Top-entry Agitator

1、Motor: 1、Explosion proof type、Non-explosion-proof type

2、Energy-efficient type、Non-energy-efficient type

2、Reducer:1、R series(Coaxial type)

2、K series(Bevel gear type)

3、F series(Parallel shaft type)

3、Coupling:1、GT Rigid convex type

2、HL Cylindrical pin type

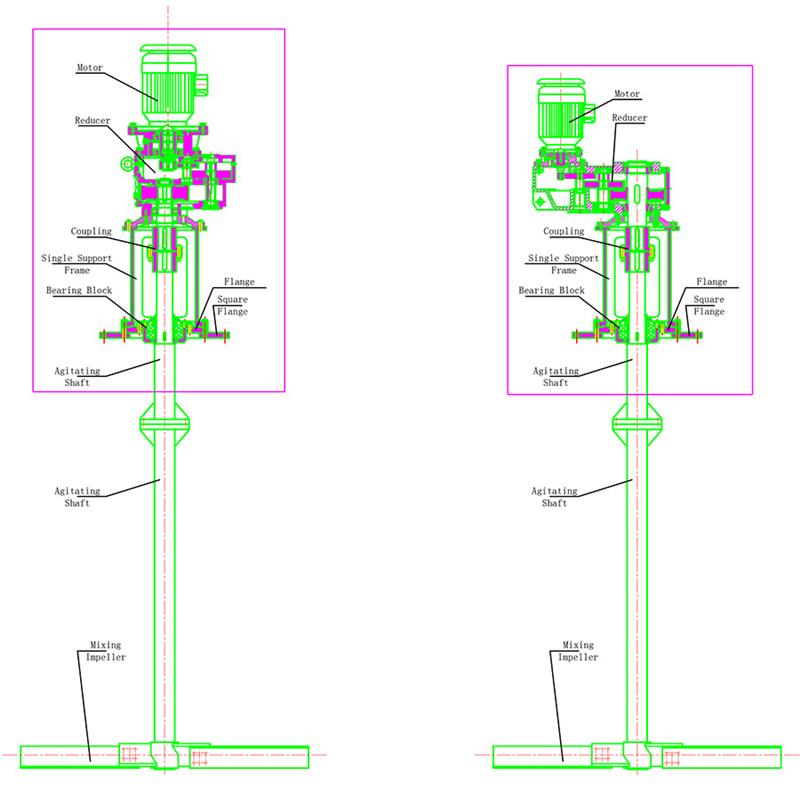

4、Frame: 1、DXJ Single support type

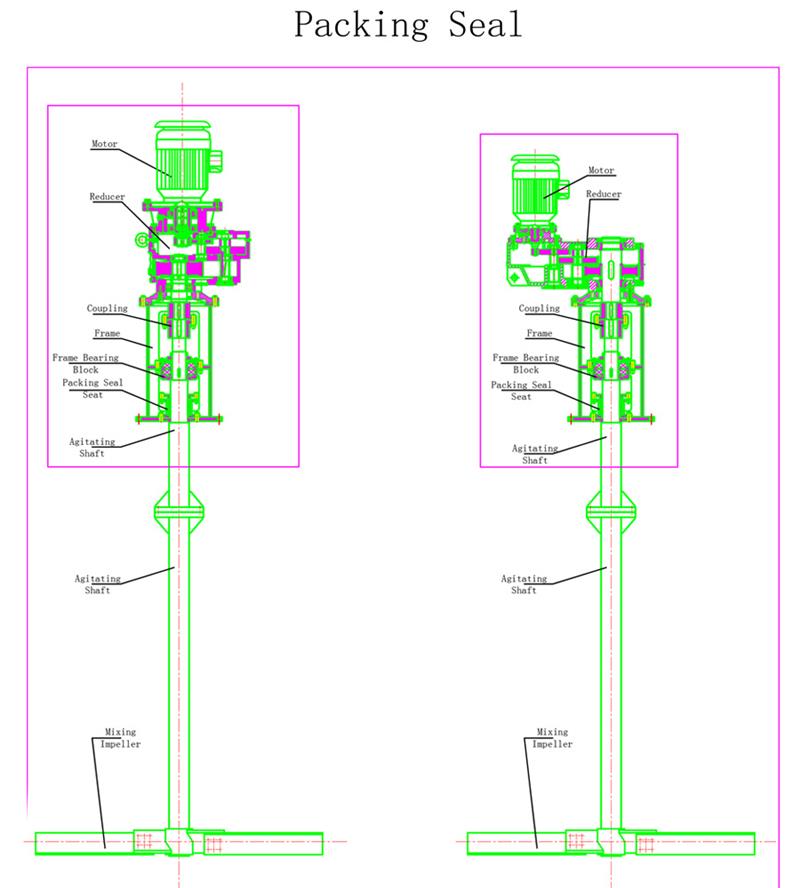

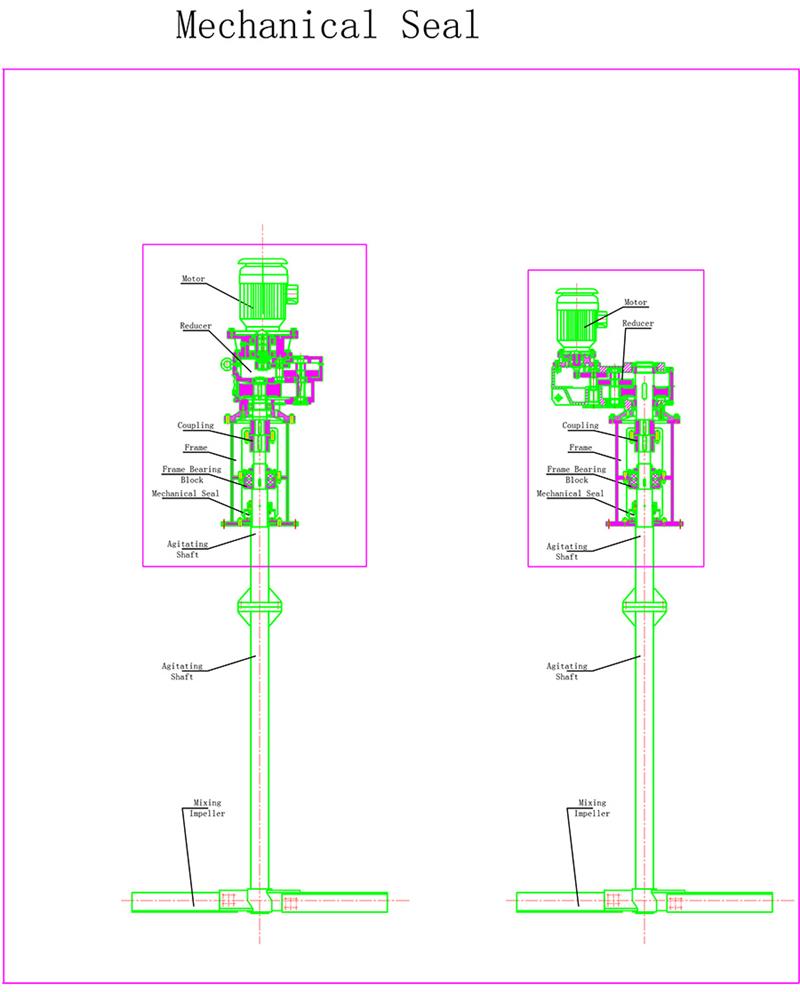

2、LDJ Single support type(can add mechanical seal or packing seal at the bottom of frame)

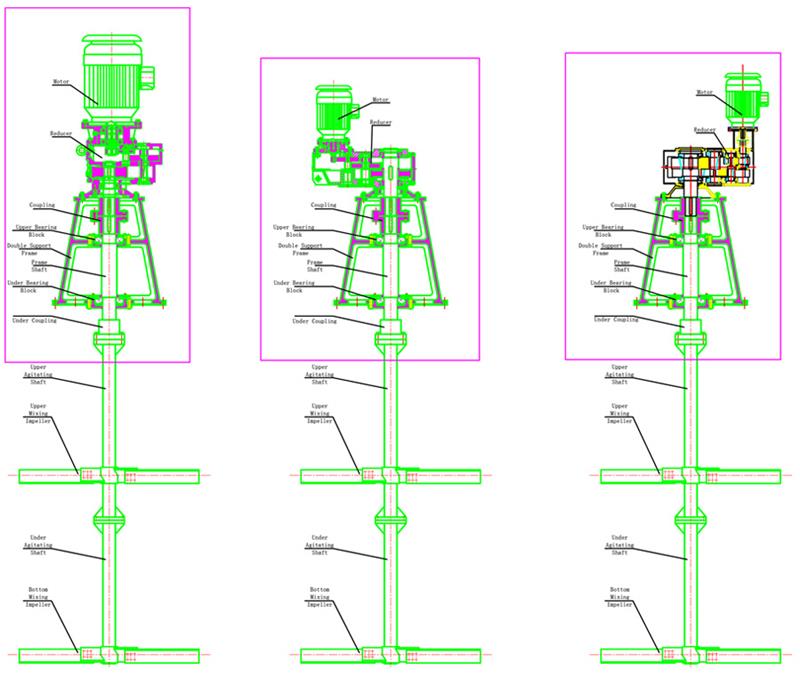

3、FZ Double support type

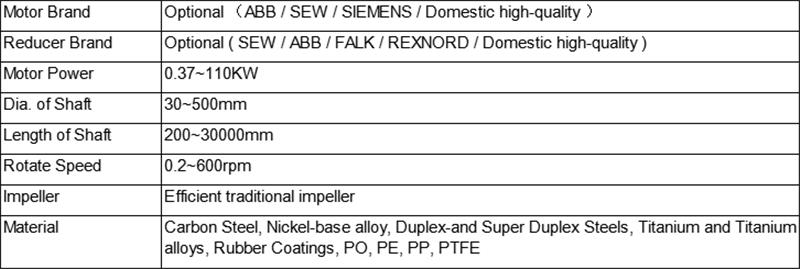

Agitator Parameter

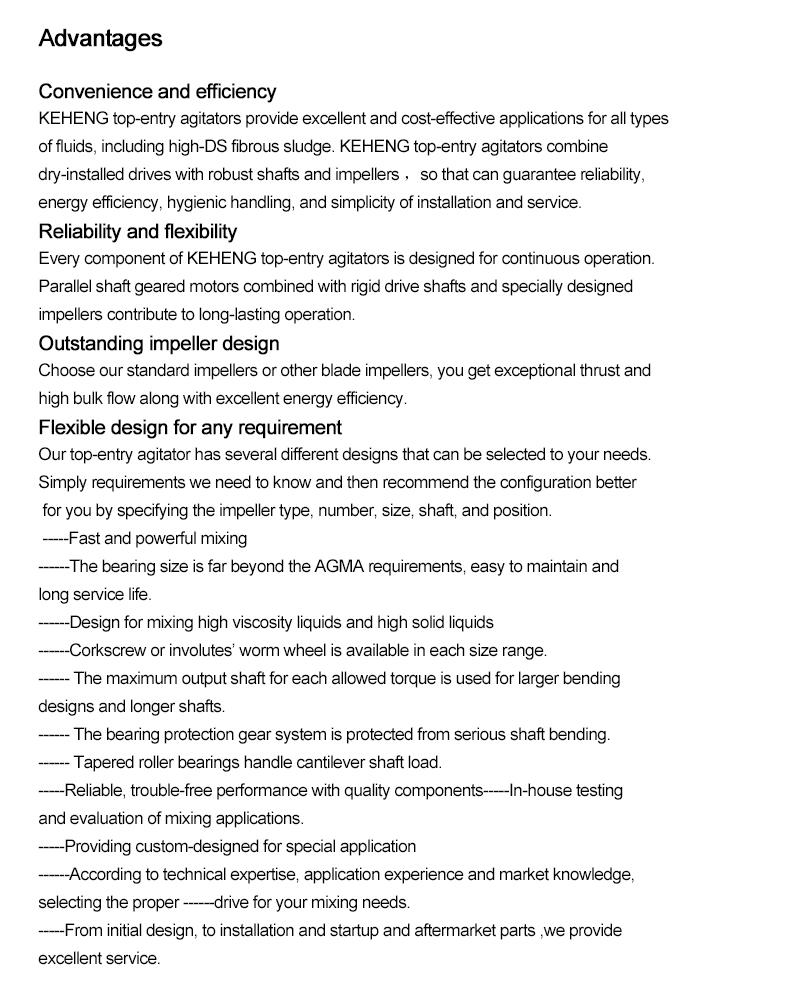

KEHENG top-entry agitator, since 1989, we have helped processing factories across the globe find the mixers and other equipment they need to meet their specific applications. Based on your specific mounting, flow pattern, and mixing requirements, we can help you select the top entry mixers that will best meet your needs, as well as suggest the impeller design and position that will offer a customized solution for nearly any agitation and mixing process. Our sales engineers are available to consult with you to determine which product or custom built equipment will be the best fit in your processing operation.

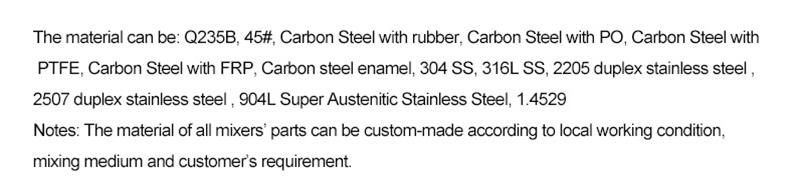

Material

Application

• Bulk chemical

• Polymer

• Specialty chemicals

• Formula consumer goods

• Bio-fuels and bio-refineries.

• Flue-gas desulfurization of Coal-fired plants

• Wet process

• Oil tank

Application range of mixing equipment in industrial production

Mixing equipment has a wide range of applications in industrial production, especially in the chemical industry, where many chemical production applications are more or less agitated. Let us know in detail the application range of mixing equipment in industrial production.

The various chemical changes in the chemical process are premised on the full mixing of the participating reactants. For the physical changes such as heating, cooling and liquid extraction, and gas absorption, it is often necessary to use a stirring operation to obtain a good effect. Mixing equipment is used as a reactor in many applications. For example, in the production of three major synthetic materials, the agitation equipment as a reactor accounts for about 90% of the total number of reactors. Other industries such as fuel, pharmaceuticals, pesticides, paints, etc., are also widely used. The non-ferrous metallurgical department has conducted investigations and power measurements on the mixing equipment in the national non-ferrous metallurgical industry. The result is that the application range of many wet-process workshops is so extensive, due to the operating conditions of the mixing equipment (such as concentration, temperature, residence time, etc.). It has a wide controllable range and can adapt to diversified production.

Stirring plays a very important role in accelerating the progress of the reaction between liquids that are incompatible with each other or between liquids and solids. Because the rate at which one phase is mixed into the other phase increases, the contact surface increases and the material interacts at a greater rate. In some cases, agitation is an important factor in creating good conditions during the reaction. For example, heat transfer is enhanced, local overheating is reduced, and material coking during heating is avoided. For example, in the production of high-pressure polyethylene, due to the action of the agitator, the material has a certain residence time in the reactor, and more importantly, the catalyst is evenly distributed in the device to prevent local violent polymerization and cause explosion. Therefore, the stirring equipment plays a very important role in industrial production.

The company has a number of professional technicians in mixing equipment design, with rich practical experience and design experience, and can carry out targeted mixing design according to the characteristics of different industries. According to the size of the tank or tank provided by the customer, the medium, the viscosity, the purpose of mixing, etc., timely design a stirring scheme that satisfies the customer. Optimized design of mixing scheme and mixing paddle type, fluid dynamics and force calculation of key components, mechanical engineering structure optimization design, according to professional standard specifications, to ensure the provision of technology and products to meet customer needs.

Hot Tags: industrial tank agitator, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China