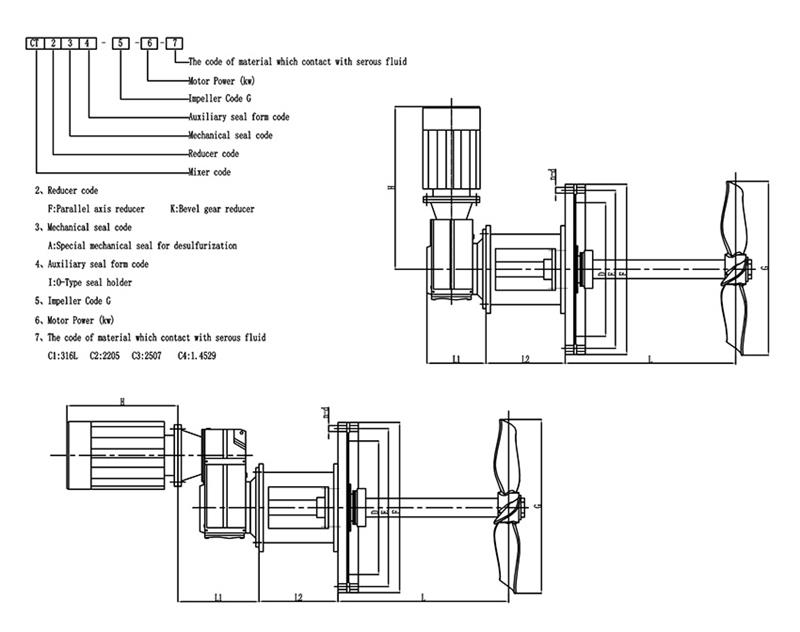

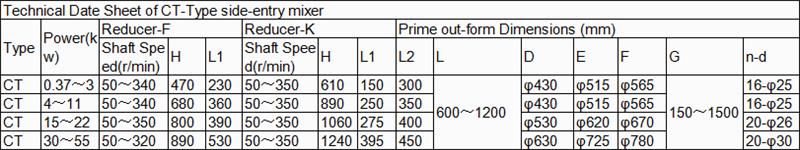

Introduction of CT-Type Side-entry mixer:

Use of flue gas desulfurization: mainly prevent the solids setting from the slurry tank and ensure that the slurry can be transported uniformly to the next process. Strengthen the diffusion of oxidized air, also promote the oxidation of calcium sulfite, the growth of gypsum crystal and the dissolution of limestone.

Using this equipment has many advantages, such as small investment, convenient operation, high efficiency, low power consumption, low static electricity generated in medium and guarantee product quality.

This type of mixer also can be used for wastewater treatment and paper-making industry.

Material

The material can be: Q235B, 45#, Carbon Steel with rubber, Carbon Steel with PO, Carbon Steel with PTFE, Carbon Steel with FRP, Carbon steel enamel, 304 SS, 316L SS, 2205 duplex stainless steel , 2507 duplex stainless steel , 904L Super Austenitic Stainless Steel, 1.4529

Notes: The material of all mixers’ parts can be custom-made according to local working condition, mixing medium and customer’s requirement.

Application of mixer in industrial production

Mixing equipment is widely used in industrial production, especially in the chemical industry, where many chemical production uses more or less mixing operations. The various chemical changes in the chemical process are conditional on the intensive mixing of the participating materials. For the physical changes such as heating, cooling and liquid extraction, and gas absorption, it is often necessary to use a mixing operation to get a good effect.

The stirring operation is divided into mechanical stirring and air stirring. The airflow agitation is to use a gas bubble to pass through the liquid layer to agitate the liquid, or to cause the bubble group to rise in a dense state to promote a convective circulation of the liquid by a so-called airlifting action.

Mixing equipment is used as a reverberator in many applications. For example, in the production of the three major components, the mixing device acts as a reverberator, accounting for about 90% of the total number of reverberators. Other industries such as dyes, pharmaceuticals, pesticides, paints, etc., the use of mixing equipment is also very extensive.

The non-ferrous metallurgical department conducted investigations and power tests on mixing equipment in the national non-ferrous metallurgical industry. As a result, many of the wet-processed vehicles consumed more than 50% of the power used in mixing operations. The scale of the use of mixing equipment is so wide, and because of the wide controllable scale of mixing equipment operating conditions (such as concentration, temperature, residence time, etc.), it is also accustomed to diversified production.

Hot Tags: industrial mixer for liquid soap, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China