Introduction of PV-Belt-Type Side-entry mixer:

Installing a side-entry mixer in the oil tank, is used for mixing oils or other medium and then reach the purpose of harmonization, heat transfer, homogenization and prevention of sediment accumulation. Using this equipment has many advantages, such as small investment, convenient operation, high efficiency, low power consumption, low static electricity generated in medium and guarantee product quality.

PV-Type Side-entry mixer can be installed in petroleum tank, lubricating tank, fuel oil drum, paraffin tank and some storage tanks for additive and other medium which need to be stirred.

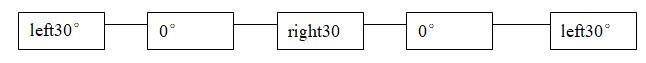

Swing Angle changes of PV-Type Side-entry mixer

The variable insertion Angle type agitator is used to prevent the accumulation of sediments, and the change of rotation Angle as follows

Material

The material can be: Q235B, 45#, Carbon Steel with rubber, Carbon Steel with PO, Carbon Steel with PTFE, Carbon Steel with FRP, Carbon steel enamel, 304 SS, 316L SS, 2205 duplex stainless steel , 2507 duplex stainless steel , 904L Super Austenitic Stainless Steel, 1.4529

Notes: The material of all mixers’ parts can be custom-made according to local working condition, mixing medium and customer’s requirement.

What role does the mixer play in the oil chemical industry?

Mixers are widely used in many industries in our lives, and their use can bring us many benefits.

Mixers are used in petrochemical production for material mixing, dissolution, heat transfer, vegetation suspension, polymerization, preparation of catalysts, etc. For example, in the petroleum industry, mixing adjustment and refining of dissimilar crude oils, and addition of additives such as tetraethyl lead to gasoline are carried out to homogenize the raw material liquid or product. In chemical production, processes such as styrene, ethylene, high-pressure polyethylene, polypropylene, synthetic rubber, aniline fuel and paint pigments are equipped with various types of mixers.

The function of the mixer is as follows: 1 to make the material mix evenly; 2 to make the gas disperse well in the liquid phase; 3 to uniformly suspend solid particles (such as catalyst) in the liquid phase; 4 to make the other liquid phase incompatible Suspension or full emulsification; 5 to enhance the mass transfer between the phases (such as absorption, etc.); 6 to enhance heat transfer.

Hot Tags: crude oil tank mixer, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China