Introduction of V-Type Side-entry mixer:

Installing a side-entry mixer in the oil tank, is used for mixing oils or other medium and then reach the purpose of harmonization, heat transfer , homogenization and prevention of sediment accumulation.

Using this equipment has many advantages, such as small investment, convenient operation, high efficiency, low power consumption, low static electricity generated in medium and guarantee product quality.

V-Type Side-entry mixer can be installed in petroleum tank, lubricating tank, fuel oil drum, paraffin tank and some storage tanks for additive and other medium which need to be stirred.

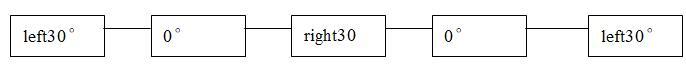

Swing Angle changes of V-Type Side-entry mixer

The variable insertion Angle agitator is used to prevent the accumulation of sediments, and the change of rotation Angle as follows.

Material

The material can be: Q235B, 45#, Carbon Steel with rubber, Carbon Steel with PO, Carbon Steel with PTFE, Carbon Steel with FRP, Carbon steel enamel, 304 SS, 316L SS, 2205 duplex stainless steel , 2507 duplex stainless steel , 904L Super Austenitic Stainless Steel, 1.4529

Notes: The material of all mixers’ parts can be custom-made according to local working condition, mixing medium and customer’s requirement.

Polishing work for side-in mixers

Many users will polish their side-in mixers, and the benefits of side-in-side abrader polishing are numerous. Generally, after the side-in mixer is polished, it is not easy to fade, and it will not be affected in many harsh environments. In addition to this, there are many reasons for the side-in mixer to be polished.

In order to make the side-in mixer not fading in harsh environments, we will introduce several polishing methods for the stainless steel used, which is believed to help the next use.

1. Chemical polishing is a side-in type agitator. Due to its special metallographic structure and surface passivation film, it is difficult to be chemically reacted with the medium under normal conditions, but it cannot be corroded under any conditions. corrosion. In the presence of corrosive media and incentives (such as scratches, splashes, slag, etc.), the side-in type agitator can also be corroded by slow chemical and electrochemical reactions with corrosive media, and the corrosion rate under certain conditions It is quite fast and produces rust, especially pitting and crevice corrosion.

2, side-in type agitator surface treatment operation process: brush stainless steel pickling passivation paste - flow clean water rinse - cloth polishing and drying package, brushing passivation paste on the surface of the side-in mixer, thickness 1 -2MM, the residence time is 1-20 minutes, must pass the process.

3. The standard for pickling passivation is to see if the surface passivation film is intact. When the surface of the side-in mixer is completely covered by sub-white, the passivation is qualified, neutralized, and the surface is washed with a caustic solution. The surface shape is simple, there is no crepe pattern, no blind holes, this step can be omitted, pure water, optional process, because the stainless steel passivation paste used is a chemical product, the side-integral mixer operator needs to wear labor during operation. Protect the appliance from contact with the skin by stainless steel pickling passivation cream to avoid injury!

By doing the above work, it is possible to ensure that the side-in type agitator can be used in any environment without fading, which effectively ensures the aesthetics in use and prolongs the service life.

Hot Tags: agitator for chemical tank, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China