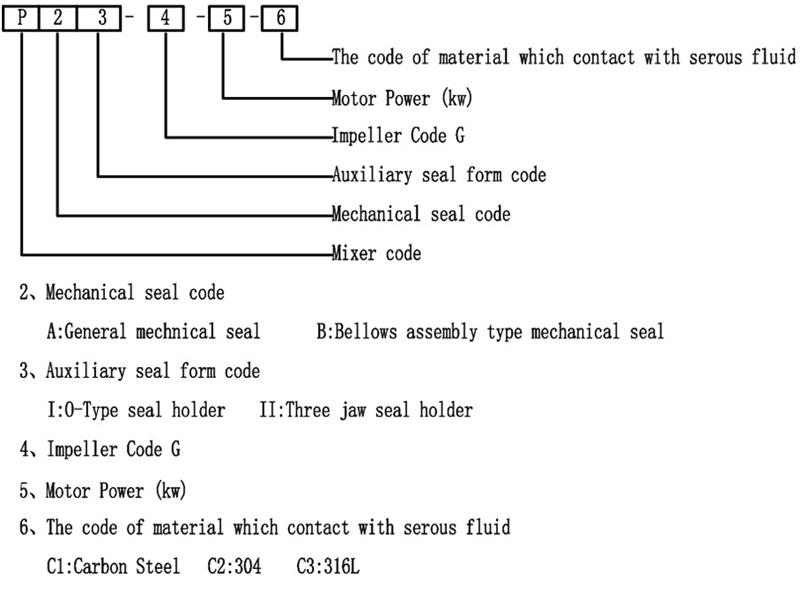

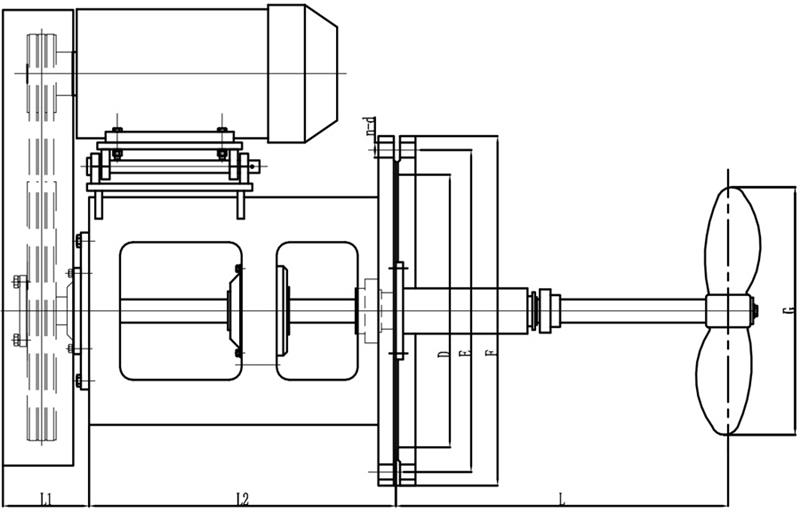

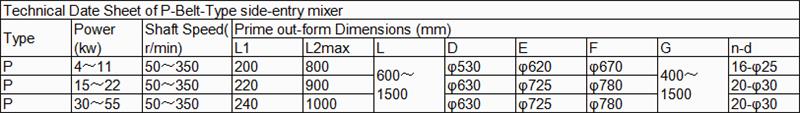

Introduction of P-Belt-Type side-entry mixer:

Installing a side-entry mixer in the oil tank, is used for mixing oils or other medium and then reach the purpose of harmonization, heat transfer , homogenization and prevention of sediment accumulation.

Using this equipment has many advantages, such as small investment, convenient operation, high efficiency, low power consumption, low static electricity generated in medium and guarantee product quality.

P-Belt-Type Side-entry mixer can be installed in petroleum tank, lubricating tank, fuel oil drum, paraffin tank, asphalt tank (for heavy rubber asphalt, basic petroleum bitumen, A Grade asphalt) and some storage tanks for additive and other medium which need to be stirred.

Material of industrial mixer for oil

The material can be: Q235B, 45#, Carbon Steel with rubber, Carbon Steel with PO, Carbon Steel with PTFE, Carbon Steel with FRP, Carbon steel enamel, 304 SS, 316L SS, 2205 duplex stainless steel , 2507 duplex stainless steel , 904L Super Austenitic Stainless Steel, 1.4529

Notes: The material of all mixers’ parts can be custom-made according to local working condition, mixing medium and customer’s requirement.

What is the effect of mixing different materials with a side-in mixer?

The mixing effect of the side-in type agitator should be observed in the process of use, but some people have not officially used the side-in type agitator, so some knowledge of the side-in type agitator is not enough. To understanding. If this knowledge of the side-in mixer is not clear enough, you can look down.

Side-in agitators use agitation of components of different media: the general viscosity in our life refers to the resistance of the fluid to flow, and viscosity is a property of the fluid. When the fluid flows in the pipeline of the side-in type agitator, there are three states of laminar flow, transitional flow, and turbulent flow. The three flow states are also present in the side-in type agitator, and one of the main parameters determining these states is also determined. It is the viscosity of the fluid.

In the side-in agitator mixing process, it is generally considered that the viscosity is less than 5 Pa / s is a low viscosity fluid, for low viscosity medium, the small diameter of the high speed side - in - the - line agitator can drive the surrounding fluid circulation, and far away. The fluid of high viscosity medium is not the same, and it needs to be directly driven by a side-in type agitator.

Impellers for low-viscosity and medium-viscous fluids are paddle, open turbine, propulsion, long thin blade propeller, disc turbine, Bruma gold, plate and paddle, trilobal, MIG And so on. The impellers suitable for high viscosity and extra high viscosity fluids are spiral impeller, screw type, anchor type, frame type, propeller type and the like. Some fluid viscosity changes with the reaction, and it is necessary to use an impeller suitable for a wide viscosity field, such as a general-purpose impeller.

Hot Tags: industrial mixer for oil, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China