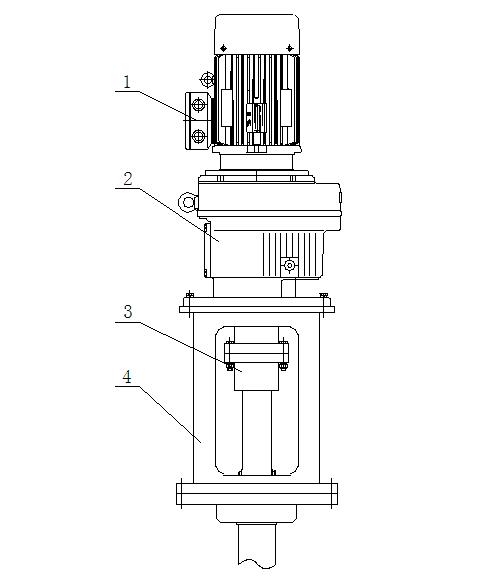

Top-entry Agitator

1、Motor: 1、Explosion proof type、Non-explosion-proof type

2、Energy-efficient type、Non-energy-efficient type

2、Reducer:1、R series(Coaxial type)

2、K series(Bevel gear type)

3、F series(Parallel shaft type)

3、Coupling:1、GT Rigid convex type

2、HL Cylindrical pin type

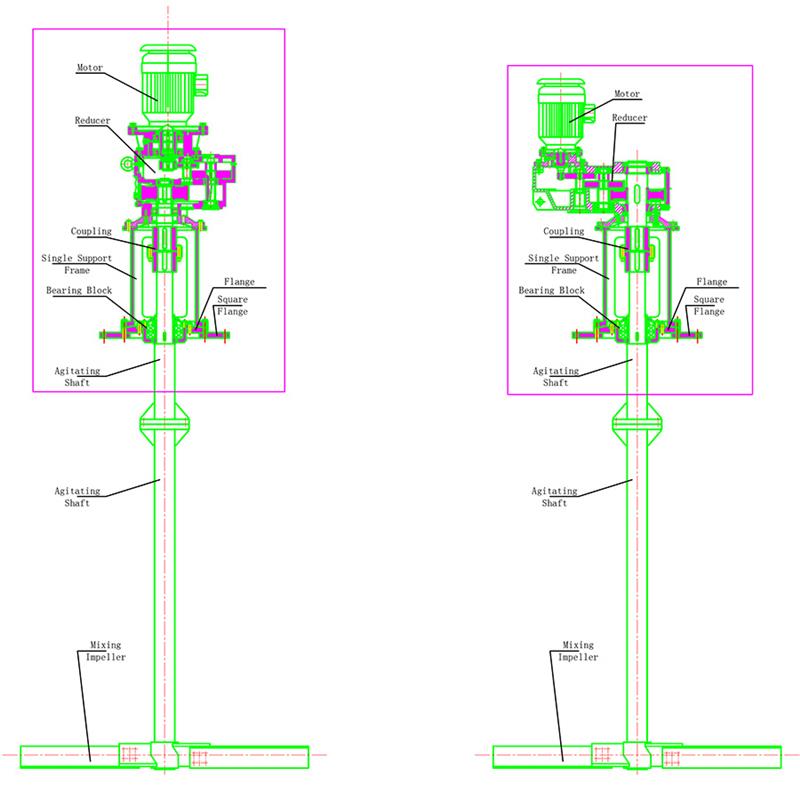

4、Frame: 1、DXJ Single support type

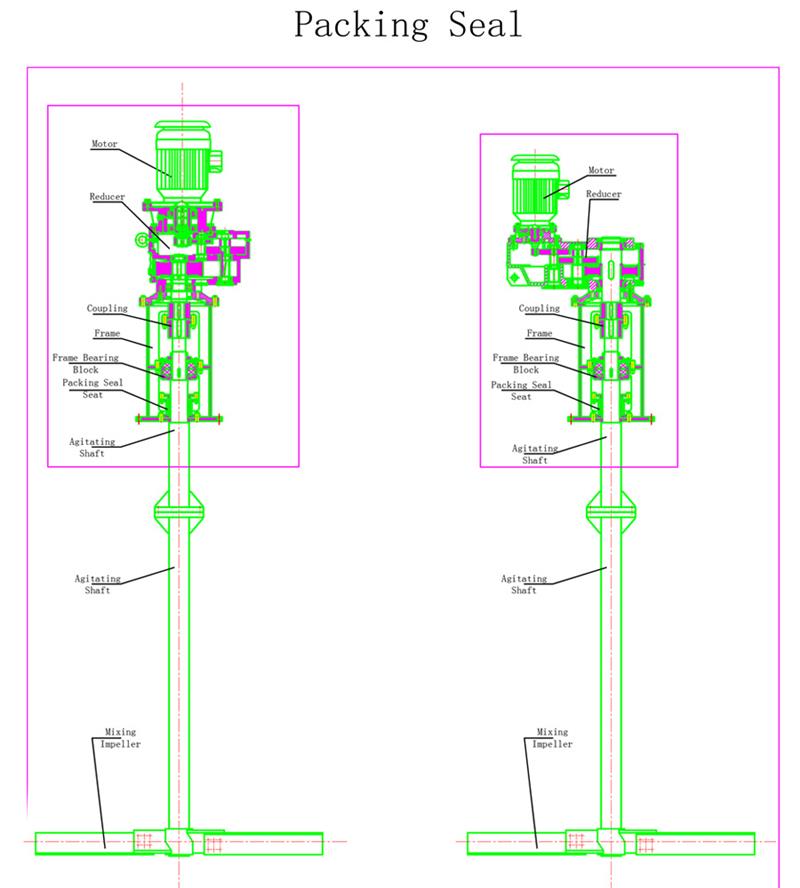

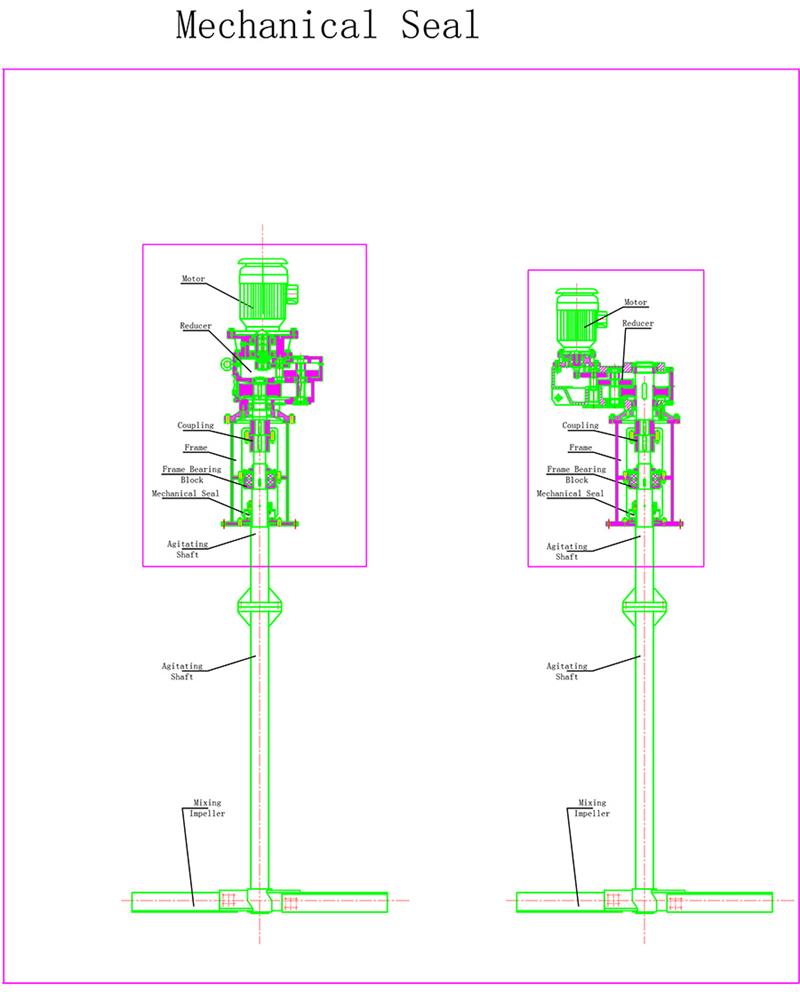

2、LDJ Single support type(can add mechanical seal or packing seal at the bottom of frame)

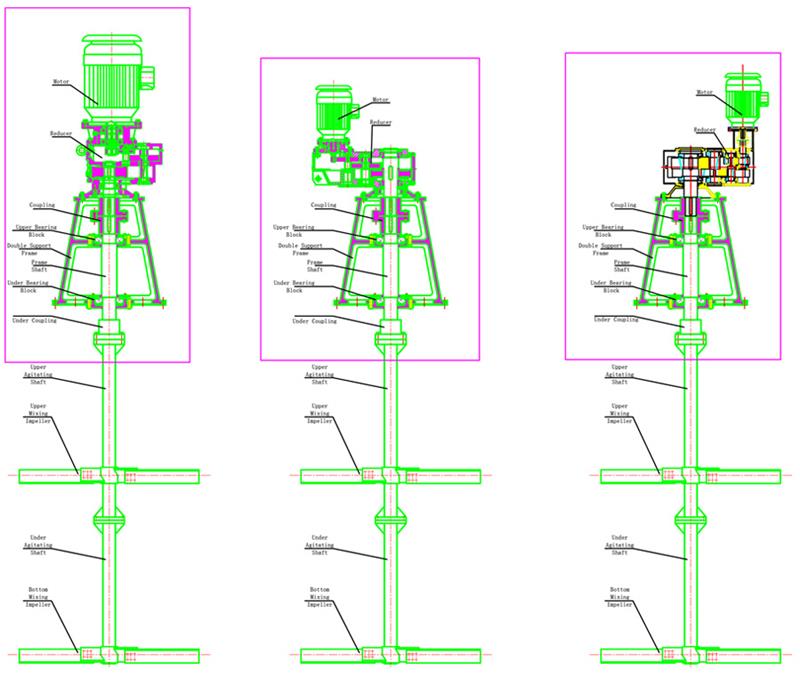

3、FZ Double support type

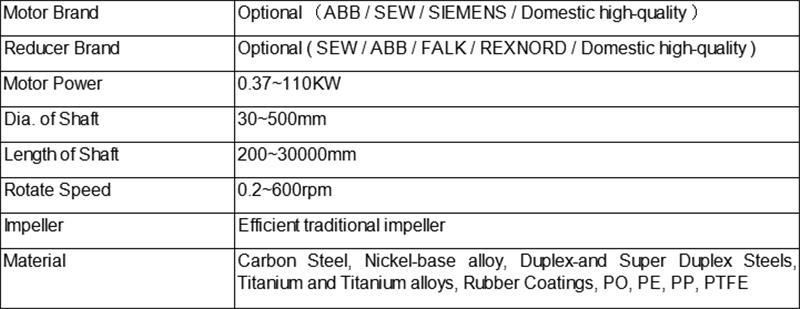

Agitator Parameter

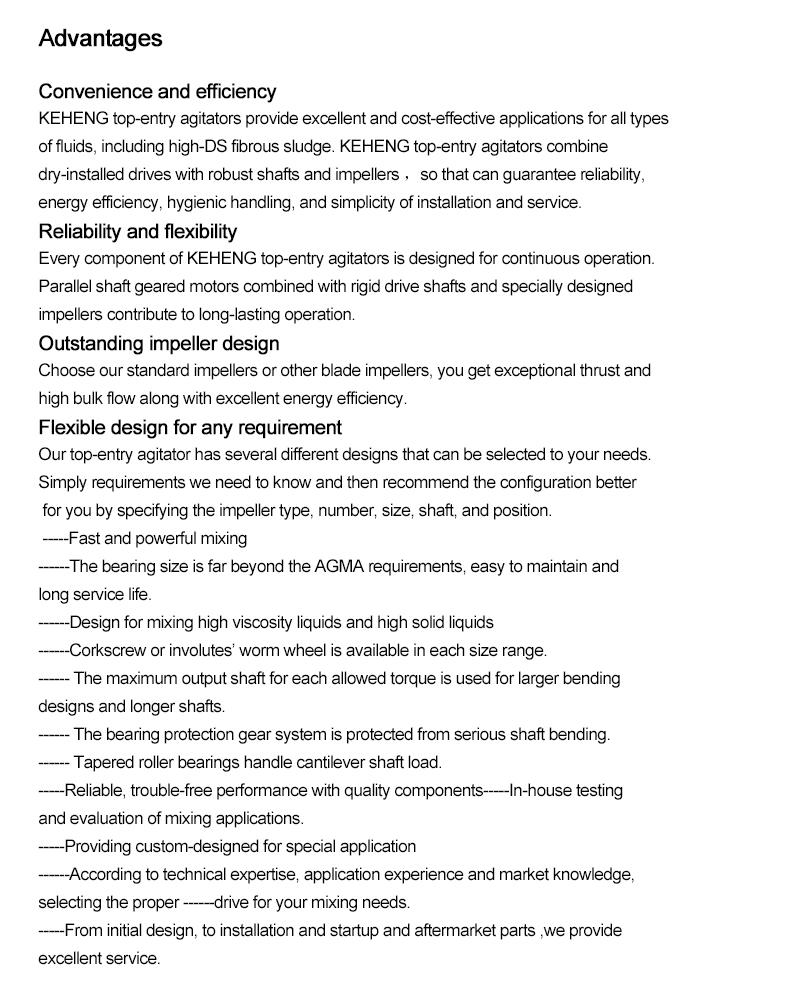

KEHENG top-entry agitator, since 1989, we have helped processing factories across the globe find the mixers and other equipment they need to meet their specific applications. Based on your specific mounting, flow pattern, and mixing requirements, we can help you select the top entry mixers that will best meet your needs, as well as suggest the impeller design and position that will offer a customized solution for nearly any agitation and mixing process. Our sales engineers are available to consult with you to determine which product or custom built equipment will be the best fit in your processing operation.

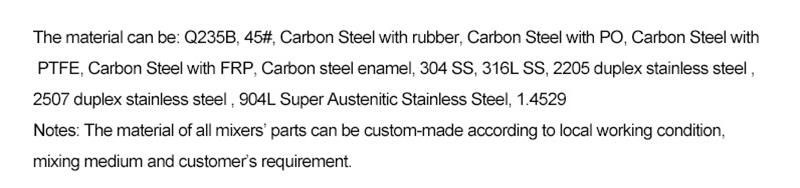

Material

Application

• Bulk chemical

• Polymer

• Specialty chemicals

• Formula consumer goods

• Bio-fuels and bio-refineries.

• Flue-gas desulfurization of Coal-fired plants

• Wet process

• Oil tank

Different installation forms of the mixer will produce different flow fields

Installation form Different installation forms of the mixer will produce different flow fields, which will make a significant difference in the mixing effect. Usually the mixer installation form is divided into the following types:

1) Vertical center agitation installation form It is characterized in that the agitator shaft and the agitator are arranged on the center line of the agitation tank, and are symmetrically arranged. The driving mode is belt transmission or gear transmission or through deceleration transmission, and is also directly driven by the motor. The mixing equipment power can range from 0.1kw to hundreds of kilowatts, and the usual power range is 0.2-22kw. Generally, the power is less than 3.7kw for small size, 5.5 to 22kw for medium size, and greater than 22kw for large size. Small mixers are used in the food industry. The low speed type is lower than 100r/min, the medium speed type is 100~400r/mm, and the high speed type is more than 400r/mn. Depending on the application, the structure of the blade can be combined in a variety of ways, with a three-blade propeller type. Turbine is the main body and can be combined into a variety of structural forms to suit a variety of uses. Most of these mixing equipment have been standardized in foreign countries. The speed range is from 300 to 360 r/min, and the motor power is from 0.4 to 15 kW. It is driven by a first-stage deceleration with belt drive or gear transmission.

2) Eccentric stirring installation form It is characterized in that the agitator is installed in the eccentric position of the vertical container. This installation form can prevent the liquid from rotating in the vicinity of the agitator, and the effect is similar to that of the installation baffle. The center line of the stirring shaft is offset from the axis of the container, which causes the pressure distribution of the liquid flow at different points to be different, and the relative movement between the liquid layers is enhanced, thereby increasing the turbulence between the liquid layers, so that the stirring effect is obviously improved. However, eccentric agitation is likely to cause vibration of the device during operation. Generally, such installation forms are only used on small devices.

3) Tilting agitation installation form features: Install the agitator directly on the upper edge of the tank, clamp and fix it with the splint or chuck and the edge of the cylinder. The stirring shaft is inserted obliquely into the container for mixing. It is suitable for mixing the container. A cylindrical structure or a square open mixing device prevents eddy currents. The mixing device of this type of installation is more flexible and flexible, easy to use and maintain, simple in structure and light in weight. It is generally used on small equipment, and the power used is 0.1-2.2kw. The mixer with one or two layers of blades is used. 36 ~ 300r / min range.

Hot Tags: flange mount gear drive mixer, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China