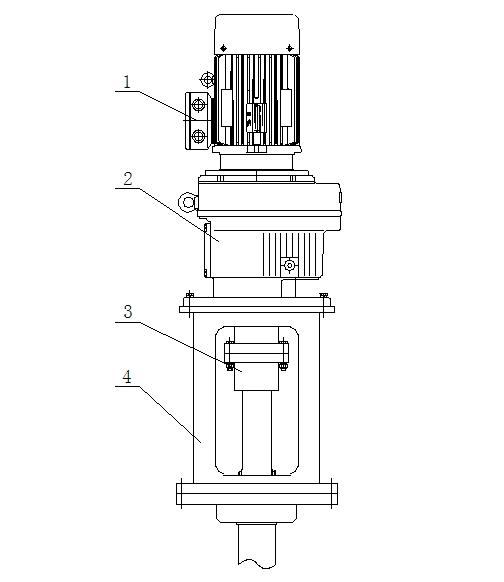

Top-entry Agitator

1、Motor: 1、Explosion proof type、Non-explosion-proof type

2、Energy-efficient type、Non-energy-efficient type

2、Reducer:1、R series(Coaxial type)

2、K series(Bevel gear type)

3、F series(Parallel shaft type)

3、Coupling:1、GT Rigid convex type

2、HL Cylindrical pin type

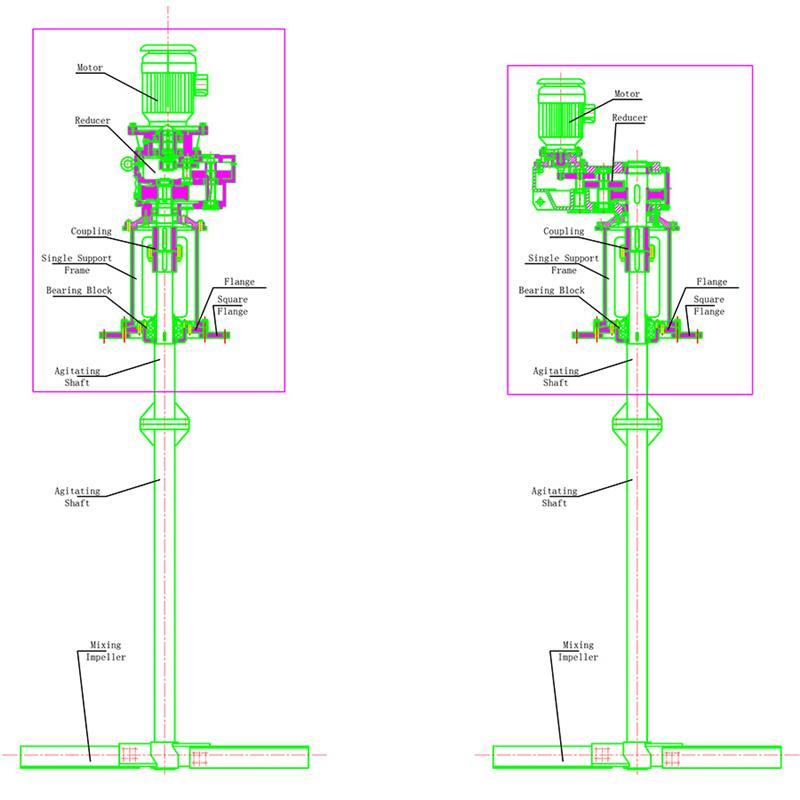

4、Frame: 1、DXJ Single support type

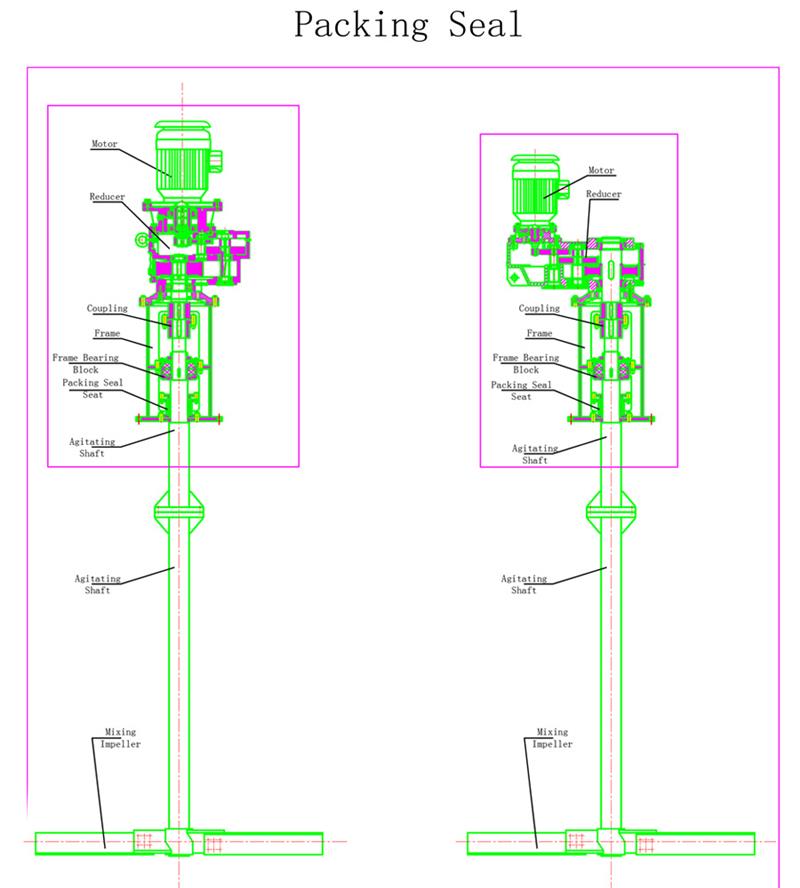

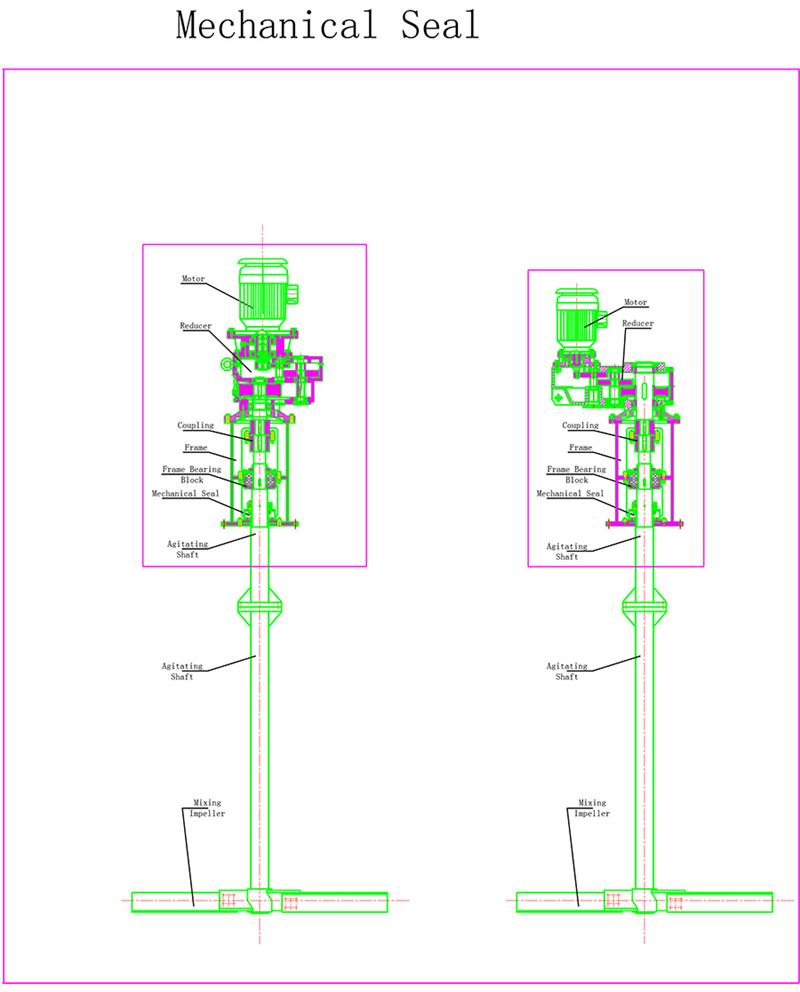

2、LDJ Single support type(can add mechanical seal or packing seal at the bottom of frame)

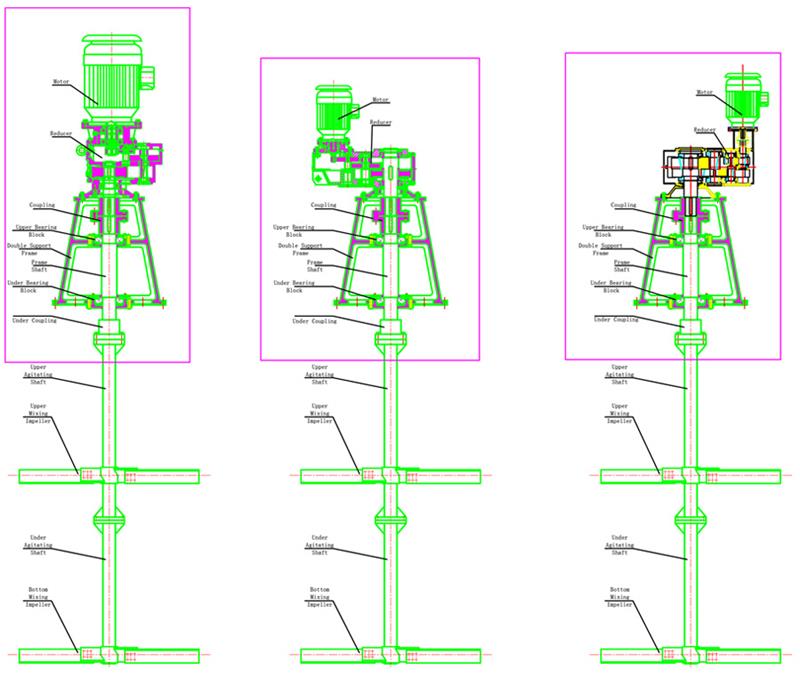

3、FZ Double support type

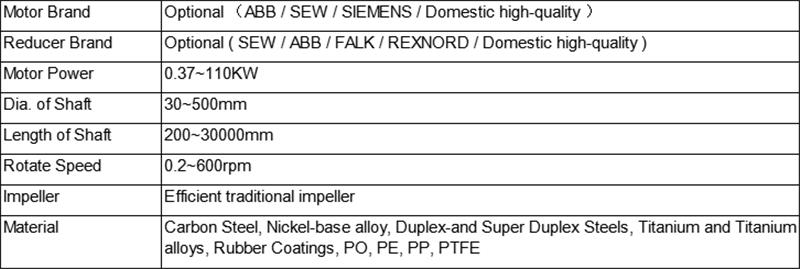

Agitator Parameter

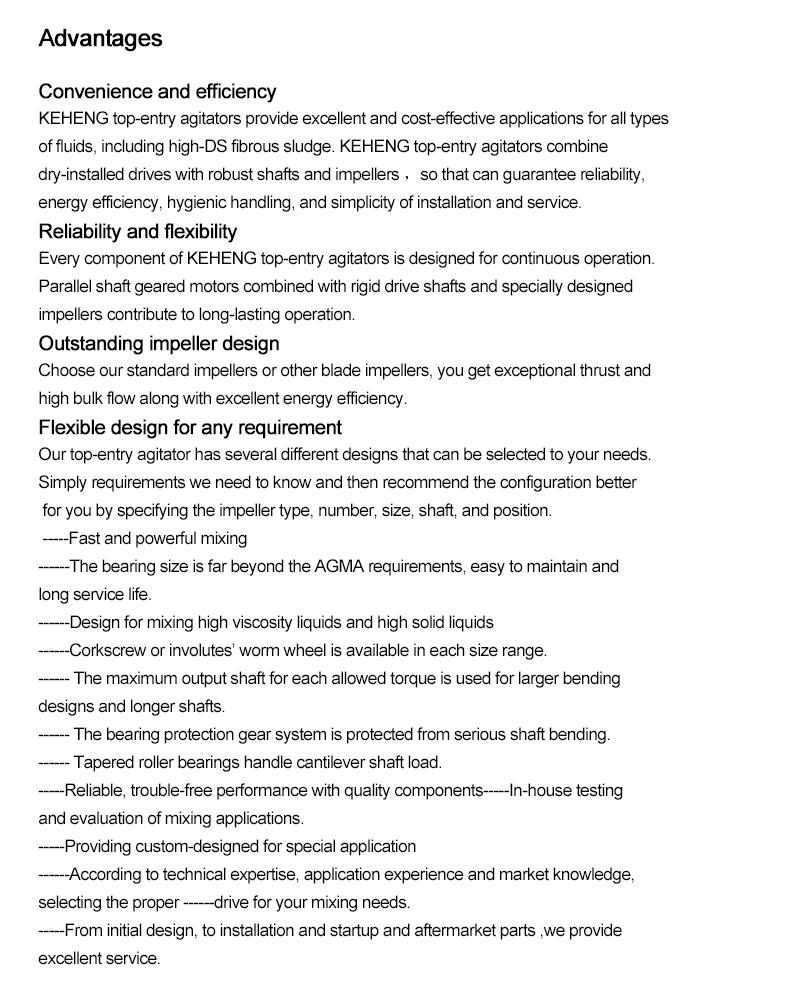

KEHENG top-entry agitator, since 1989, we have helped processing factories across the globe find the mixers and other equipment they need to meet their specific applications. Based on your specific mounting, flow pattern, and mixing requirements, we can help you select the top entry mixers that will best meet your needs, as well as suggest the impeller design and position that will offer a customized solution for nearly any agitation and mixing process. Our sales engineers are available to consult with you to determine which product or custom built equipment will be the best fit in your processing operation.

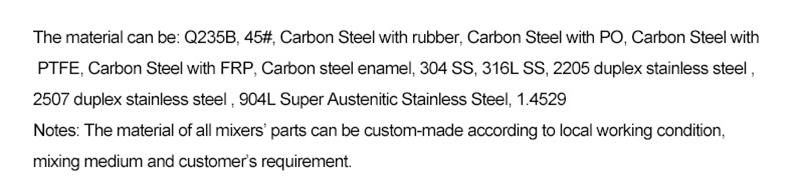

Material

Application

• Bulk chemical

• Polymer

• Specialty chemicals

• Formula consumer goods

• Bio-fuels and bio-refineries.

• Flue-gas desulfurization of Coal-fired plants

• Wet process

• Oil tank

Vertical mixers come in many forms. Commonly used vertical mixers mainly consist of: motor wheel, motor, barrel, screw, discharge port, cleaning port, pulley, window, ladder, inlet, electrical box, circulating drop port , the feeding port and the like.

Vertical mixer maintenance

1. After using the equipment for each shift (times), it must be processed for 5s inside and outside the equipment and surrounding areas.

2. Check the condition of the agitator (balance and friction) of the equipment every month.

3, the machine should be placed in the ventilation position, the Niken motor function as heat dissipation, extending the life of the motor.

4. Regularly check if the belt is loose. The motor should be moved outward until the belt is tightened.

5. Feed the grease to the bearing to ensure lubrication between the bearings.

6. If there is any fault in the mechanical operation, it must be shut down and the power supply can be stopped.

7. Before the machine is running, check whether the screw of the blade in the barrel is loose. If it is loose, it should be tightened.

8. It is forbidden to mix tools, hard objects and ribbons into the barrel.

The vertical mixer works by the rapid rotation of the screw to raise the material from the bottom of the barrel from the center to the top, and then throw it away in an umbrella shape, returning to the bottom, so that the raw materials can be tumbling up and down in the barrel, and a large amount can be put in a short time. The raw materials are evenly mixed.

Vertical mixer operating procedures and maintenance an operational process:

1. The operating staff must be familiar with the method of use of the equipment used to ensure safe operation;

2. Before use, check whether the equipment and the barrel are clean and ensure that they are clean and ready to use.

3. The number in the model number of the device is the stirring capacity of the device, in kilograms. When using the equipment, be careful not to stir the mixing; to avoid damage to the equipment and uneven mixing, but burn the motor.

4. When pouring plastic into the barrel, be careful not to let other particles and paper scraps enter, and the material must be kept pure.

5, the mixing time according to the size of the barrel of the equipment. It can be set for 3-7 minutes, and it is better to stir 2 times.

6. When the equipment is running, the cover must be covered and locked. It is strictly prohibited to violate.

7. When releasing the plastic granules in the barrel, pay attention to prevent the material from overflowing out of the barrel and outside the bag.

8. If the equipment fails or makes abnormal noise, immediately stop the machine and report to the squad leader or equipment department personnel. The squad leader or equipment department personnel shall follow the equipment failure report and maintenance procedures to confirm the fault before starting.

9. Before using or refueling, turn off the power of the equipment and carry out 5s treatment on the inside and outside of the equipment and surrounding areas to avoid mixing.

Hot Tags: vertical tank agitator, China, manufacturers, suppliers, factory, buy, customized, quotation, made in China